Exploring Texas Instruments' Robotics Innovations at Embedded World 2024

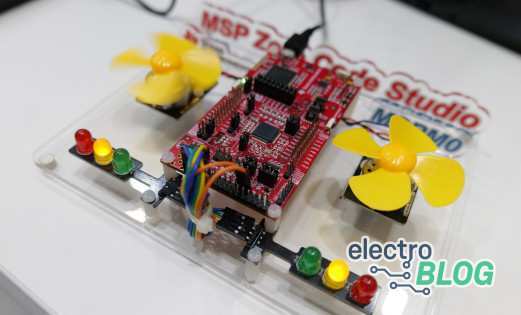

Texas Instruments (TI) has captured the spotlight at Embedded World 2024 with its "Robotics Wall," a comprehensive showcase demonstrating the intricate blend of computing, motor control, sensing, and communication technologies that drive today's robotics. This display highlights Texas Instruments' pioneering contributions to the field of automation and robotics.

Unveiling Texas Instruments' Robotics Wall

At the heart of Embedded World 2024, Texas Instruments (TI) presented a fascinating feature known as the "Robotics Wall". This innovative display served a dual purpose: to showcase the cutting-edge technologies powering modern robotics and to demonstrate Texas Instruments' pivotal role in pushing the boundaries of what's possible in automation and intelligent machinery.

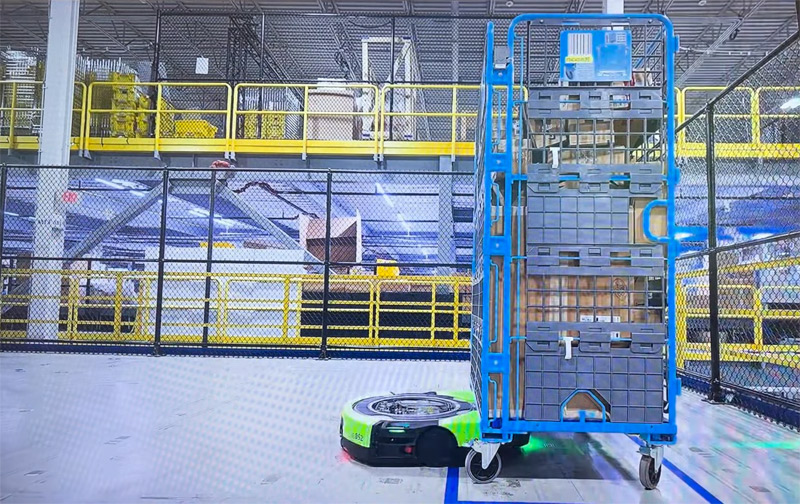

A standout aspect of the Robotics Wall was its highlight on an Amazon warehouse robot, a quintessential example of Texas Instruments' technology in action. This robot, designed to navigate the bustling aisles of Amazon's vast warehouses, display's the efficiency and precision that Texas Instruments' components bring to the table.

The Robotics Wall provided detailed insights into TI’s technology used in these types of robots, such as their Arm®-based processors, which are designed for functional safety. The wall also showcased their offer on advanced motor control, sophisticated sensing technologies, and robust communication frameworks Each element was designed to work in harmony to achieve optimal performance. This breakdown offered an in-depth look at the complexity and sophistication behind the robotics technology that Texas Instruments has pioneered, laying bare the intricacies involved in creating machines that can perform tasks with near-human precision.

Exploring the Sensory Subsystem

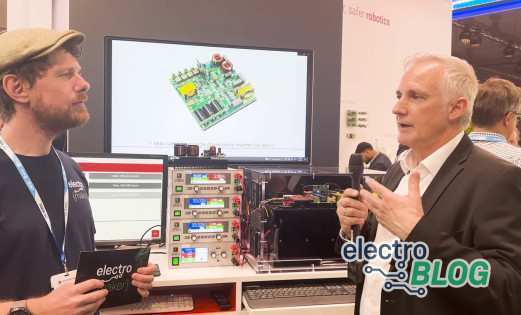

In an illuminating segment of our exploration, we were introduced to Thomas, a key figure at Texas Instruments, who plays a crucial role in elucidating the functionalities and intricacies of the various robotics subsystems. Thomas's insights provided us with a deeper understanding of the technological marvels behind the Robotics Wall, particularly focusing on the sensory components that are pivotal in robotics today.

Central to our discussion was the IWR6843 mmWave radar sensor, a standout piece of technology from Texas Instruments that represents a significant leap forward in robotic sensing capabilities. This mmWave radar sensor is engineered to offer unparalleled accuracy and reliability in object detection and navigation, critical for the autonomous operations of robots in complex environments.

Moreover, the importance of adhering to rigorous safety standards was a focal point, with specific emphasis on the IC 61 496 test 5 safety standard. This standard ensures that robotic devices, equipped with the IWR 6843 mmWave radar sensor, meet the highest safety requirements, mitigating risks and enhancing the overall safety of automated systems. This compliance not only underscores the reliability of Texas Instruments' components but also their commitment to advancing robotics technology within the framework of global safety protocols.

The Role of Motor Control in Robotics

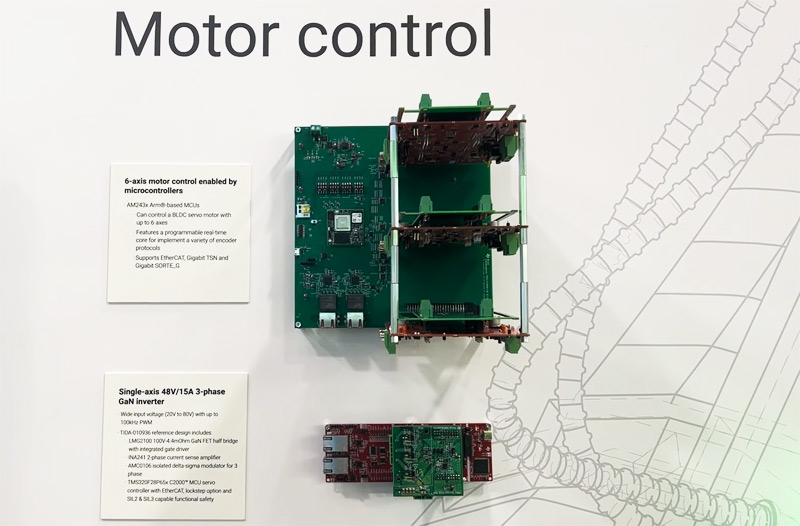

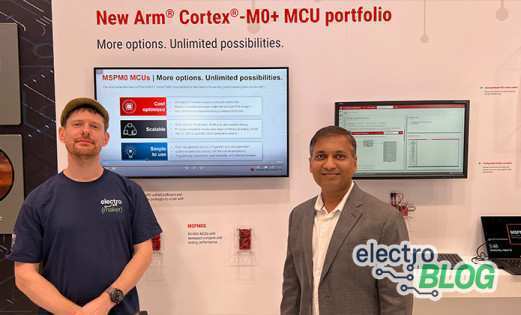

Moving deeper into the mechanics of robotics, we transition to insights from Errol, another instrumental figure at Texas Instruments, who sheds light on the motor control subsystem. Errol's expertise guides us through the nuances of how modern robotics merge the physical with the digital, underpinning the seamless operation of automated systems.

Errol introduces us to the four cornerstone technology areas that are fundamental to the advancement of robotics: motor control, computing, communications, and sensing. Each area plays a vital role in the development of robots that are not only efficient and effective but also safe and responsive to their environments. It's a holistic approach that ensures the creation of intelligent systems capable of performing complex tasks with precision.

Particularly, the focus on motor control brings to the forefront the significance of Gallium Nitride (Gan) technology. This technology is revolutionizing motor control by offering solutions that are not just robust and reliable but also compact and energy-efficient. Errol highlights how Gan technology facilitates the creation of robots that are smarter, safer, and more adaptable, fitting into a wide range of applications from industrial automation to personal robotics. The benefits of using Gan, including enhanced power density and efficiency, mark a pivotal shift towards designing robots that can operate more autonomously and interact more harmoniously within human-centric environments.

Advantages of Gan Technology in Robotics

The advent of Gallium Nitride (Gan) technology marks a transformative era in robotics, offering substantial improvements over traditional silicon-based solutions. At the forefront of this revolution is Texas Instruments' TIDA-010936 servo drive, a prime example of Gan's application in robotic systems. This servo drive embodies the cutting-edge by utilizing Gan technology to achieve remarkable efficiency and performance in a compact form factor, making it an ideal component for advanced robotic systems.

The benefits of Gan technology in robotics are manifold. Higher efficiency and power density are among the most significant advantages, allowing for more powerful robotic systems that consume less energy and operate more effectively. Furthermore, the superior heat dissipation capabilities of Gan components contribute to longer operational lifespans and reduced need for bulky cooling systems, enabling sleeker and more agile robots. These technological advancements pave the way for robots that can perform more tasks with greater precision and reliability.

For more information visit:

https://www.ti.com/applications/industrial/robotics/overview.html

Leave your feedback...