Rfid Security Cat Feeder

About the project

I have 2 cats. I need a way to keep the Tabby from eating the Void’s food and I do not want to pay $200-$250 on a microchip security feeder. So what if I use my skills in Arduino control, miniature motors, 3D printing, and 3D drafting to make my own Security Cat Feeder and save money while working on a fun project?

Project info

Difficulty: Moderate

Estimated time: 1 week

License: GNU General Public License, version 3 or later (GPL3+)

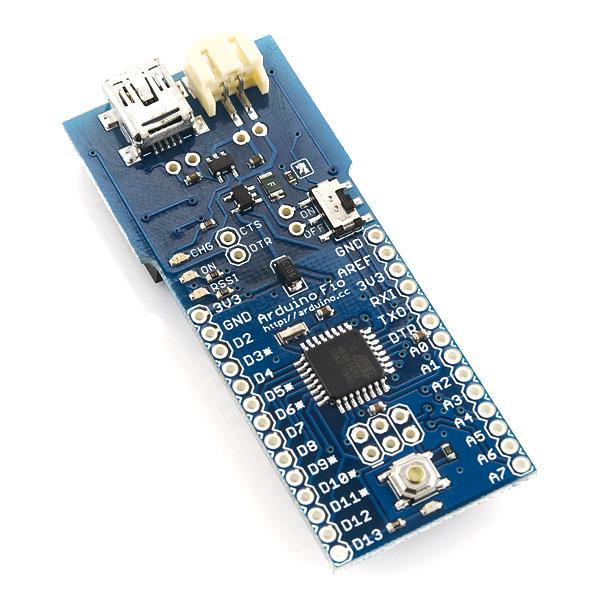

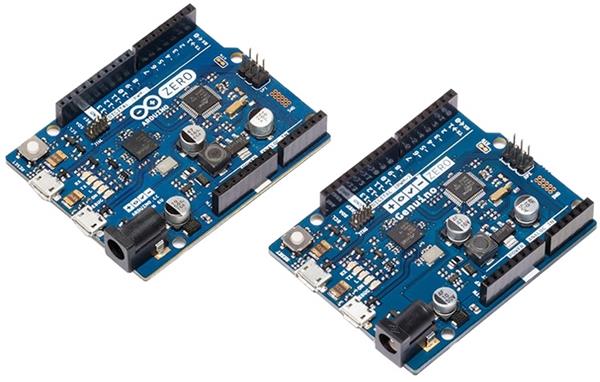

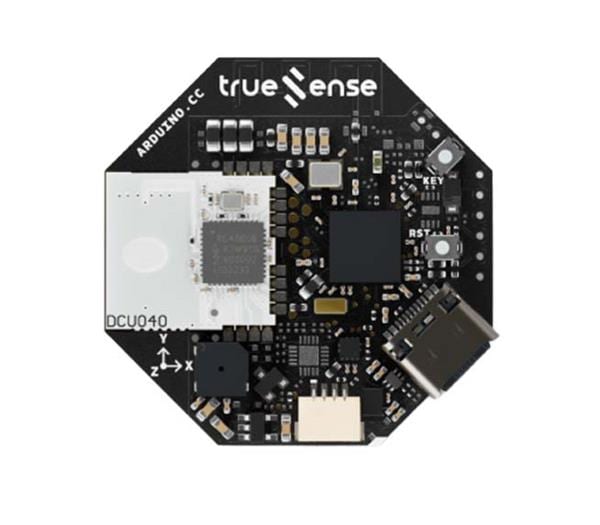

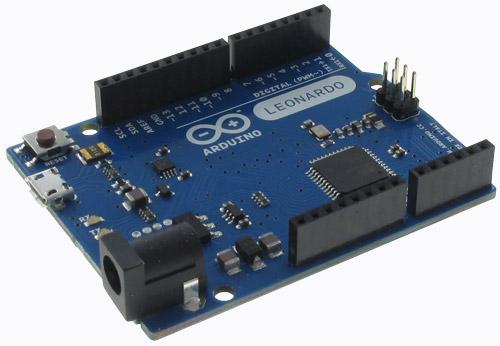

Items used in this project

Hardware components

Story

This is a 3minuet video showcase of the feeder in action.

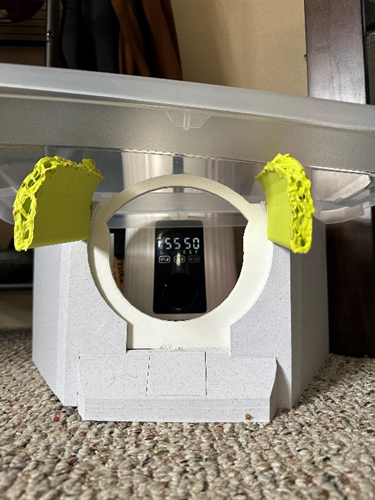

The hardest part of this project was deciding how to enact a “scan” of sorts. The Security Cat Feeders you can buy use a cat’s microchip and a microchip scanner. For my budget and skill level this seemed too complicated, so all my research went into RFID technology and how to interface it with Arduino. I did tons and tons of research and bought plenty of products to conduct experiments with. I thought I could make my own RFID antenna, but this wound up proving far too difficult and needed much more electrical knowledge to calculate. Ultimately, I landed on the RDM 6300 board. This meant I had to use its provided antenna which is roughly the size of half a credit card. This unfortunately meant that I could not have a wide-open antenna for my kitty to stick her head through undoubtedly picking up the RFID signal in the chip I planted on her collar. Because the smaller antenna became a constant in my project I designed the Kitty-head entrance to the project in such a way that I thought the RFID chip on her collar would always catch the antenna.

My RFID Security Cat Feeder works as follows. If the antenna front and center reads the correct RFID signal from the tag on the Tabby’s collar, then an SG90 servo motor does a warning flap, then full flaps to boop her on the nose and shoo her away. A future design will investigate a closing lid instead but this was easier mechanically, so that is Version 1. I designed and 3D printed all parts of this project. The RFID chip was a small flat chip I bought online and encased in a 3D printed tag which hangs on my Kitty’s collar. The weight of it has always ensured (so far) that the tag will always be front and center so the small antenna can read it.

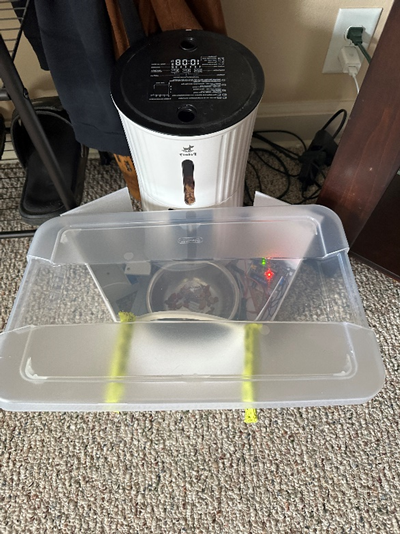

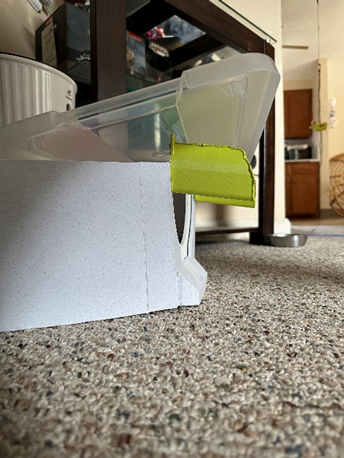

My current version of this project is viewed above, Version 1.5. This version includes a second servo motor to count how many times the feeder has been activated, and an updated Kitty’s-head hole shape. Eventually my Kitty learned that her head can not go inside the hole but her paws can so she taught herself how to use her paw like a human hand and grab the food out. This process also would leave about 5 pieces of kibble knocked outside the bowl out of reach, for every 1 piece of kibble grabbed. This quickly became a mess and frustrating so the (crude) green additions on the side keep her from doing that because she can’t position herself to grab anymore. Adding these made my kitten decide he wanted to reach over the walls and eat from the bowl that way which is why I have the lid on top. Luckily the Tabby is too fat to reach that way but my future version will finetune reaches and make entrance more comfortable for the kitten, the correct kitty who should be eating from this bowl. I will also be raising both the Kitty Head Hole and the height of the antenna, they are too low right now and makes my Void Kitty crouch to eat. V2.0 will include all these revisions in a cleaner design.

98% of my Arduino code belongs to (c) Michael Schoeffler 2018, http://www.mschoeffler.de who was able to provide the easiest explanation for me. I added a bit of code I pulled from a random forum to stop the effect of multiple reads occurring, and some simple servo positions.

Leave your feedback...