Mastering PLCs with Arduino's Opta at Embedded World 2024

Programmable Logic Controllers (PLCs) have been the backbone of industrial automation for decades, orchestrating the operations of machinery and processes with precision and reliability. Traditionally, these complex systems have required specialized knowledge to program and maintain, creating a barrier for many in the burgeoning maker community. Enter Arduino's innovative venture into industrial control with the Opta— a device designed to bridge the gap between the intricate world of PLCs and the accessible, community-driven ethos of Arduino.

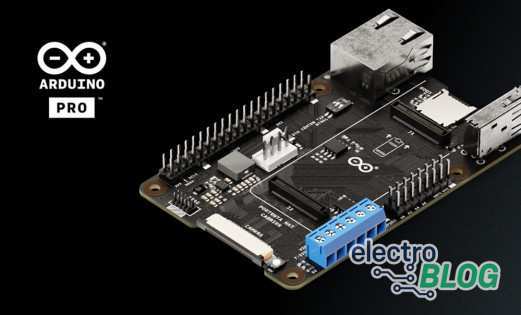

The Opta: Bridging Arduino and Industrial Control

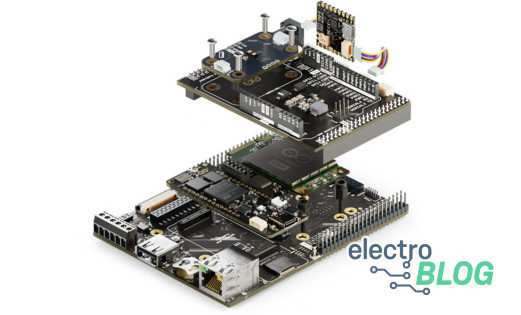

The Opta PLC boasts the dual capability to operate as a traditional PLC while embracing the flexibility and ease of use associated with Arduino-compatible devices. This unique combination has not only simplified the integration of industrial control systems for professionals but has also opened the doors for hobbyists and makers to explore the world of industrial automation like never before. The ease of use and adaptability of the Opta has garnered positive feedback from users across the spectrum, further solidifying its place in the future of industrial control.

Exploring the Opta with Arduino Pro

In a revealing conversation with Stefano from Arduino, the transformative potential of the Opta was brought to light. Designed to simplify industrial automation for both seasoned experts and curious beginners, the Opta's inclusion of programming capabilities in both traditional PLC languages and the familiar Arduino programming will help adoption from a wider range of engineers. Stefano's insights into the Opta's development and its goal to democratize access to industrial control technologies highlight the device's role in fostering a deeper understanding and engagement with automation technologies among a wider audience.

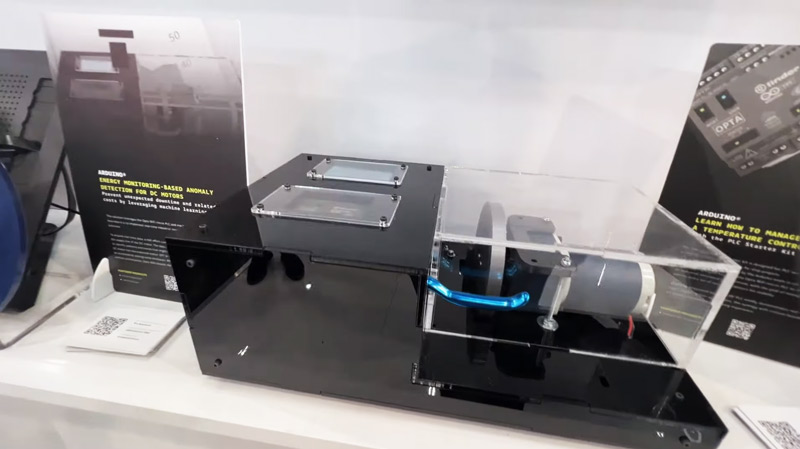

Practical Applications of the Opta: A Closer Look

A standout demonstration of its capabilities involves an energy monitoring and anomaly detection setup, featuring a DC motor paired with a hall sensor. This setup not only illustrates the Opta's ability to seamlessly integrate with industrial components but also its proficiency in conducting vital diagnostics.

The demo showcases how the Opta, through meticulous monitoring of electrical consumption, can analyze and detect anomalies in the operation of the motor. This is crucial for predictive maintenance, a cornerstone in maximizing efficiency and minimizing downtime in industrial settings. By identifying potential issues before they escalate into costly failures, the Opta empowers operators with the knowledge to take preemptive action. This proactive approach to maintenance underscores the Opta's value in not just monitoring, but actively safeguarding the operational health of industrial systems.

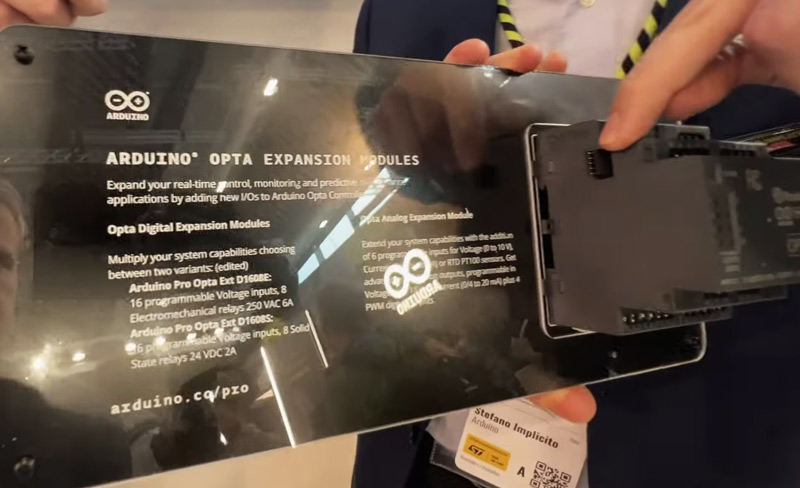

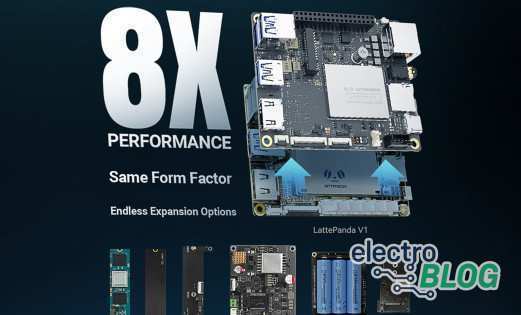

Expansion Capabilities: Meeting Industry Demand

In response to the evolving needs of the industrial sector, the introduction of digital and analog expansion modules for the Opta marks a significant advancement in its capabilities. These modules significantly increase the number of outputs the Opta can manage, facilitating a broader range of applications and greater flexibility in complex industrial settings. The ease of integration these modules offer ensures that existing systems can be upgraded without extensive modifications, streamlining the adoption of new functionalities.

The design of these expansion modules emphasizes modularity, allowing for a daisy-chain configuration that virtually eliminates the limitations on GPIO expansion. This modular approach not only caters to the demand for greater scalability within industrial automation but also embodies the forward-thinking innovation that the Opta brings to the table. By supporting limitless expansion, the Opta stands ready to meet industry demands today and in the future, ensuring that industrial systems can grow and adapt as needed without compromising on efficiency or performance.

Leave your feedback...