Blues Wireless for Arduino Opta: Add Wi-Fi and Cellular to Your PLC

It started with a painful electricity bill. Running multiple home servers for websites, file storage, and AI experiments seemed like a great idea until the energy costs began to skyrocket. Downsizing hardware and adding solar panels helped, but one challenge remained: how to monitor and control the system reliably, even when the power dropped out.

This is where industrial tools come in. A simple Arduino board wasn’t enough. Instead, the Arduino Opta PLC offers an economical way to step into the world of programmable logic controllers. Designed for industrial environments, it brings robust inputs, relay outputs, and expandability without the high price tag usually associated with PLCs.

In the video below Robin shows how to add reliable wireless to the Arduino Opta PLC with the Blues Wireless for Arduino Opta. You see a real system that reduces power costs, monitors sensors, and controls 230 V loads. The Opta handles IO and relays. Blues adds Wi-Fi and cellular with power loss alerts, free starter data, and simple routing through Notehub. Datacake provides dashboards and downlinks for remote control. You get practical wiring tips, code structure, and a full data path from sensor to cloud and back.

The Problem: Energy Use & The Need for Smarter Control

Running servers at home can feel like the ultimate maker achievement: fast hardware, reliable uptime, and complete control over your data. For a while, it worked perfectly. But then came the electricity bill. What started as a side project quickly turned into a major drain on both power and wallet, with kilowatts of energy being consumed around the clock.

Switching from bulky rack servers to smaller machines and exploring solar power helped reduce the load, but it wasn’t enough. Even a modest setup running 24/7 adds up quickly. The real challenge wasn’t just cutting power; it was knowing exactly how much energy was being used, when outages occurred, and how to keep critical systems running without constant supervision.

This is where the story shifts from one person’s home lab to a much larger issue. Rising energy costs and the demand for greater efficiency aren’t just problems for hobbyists; they’re universal challenges faced by industries, businesses, and makers alike. Whether it’s monitoring a server rack, managing a production line, or automating a renewable energy system, the need is the same: smarter monitoring, reliable connectivity, and the ability to respond in real time when something goes wrong.

Why a PLC, Not Just a Microcontroller?

At first glance, a PLC, short for Programmable Logic Controller, looks a lot like a regular microcontroller board. It can be programmed, has inputs and outputs, and runs code to control connected devices. But a PLC is more than just another board; it’s designed from the ground up for industrial use. Think of it as a PC built for the factory floor, rugged, reliable, and engineered to handle the tough jobs.

Unlike a typical Arduino Uno or similar microcontroller, a PLC integrates everything needed to safely interface with real-world machines:

- Industrial-grade I/O: Inputs and outputs are designed to handle higher voltages and currents safely.

- Opto-isolated inputs: These protect the controller from voltage spikes while allowing compatibility with a wide range of sensors.

- Relay outputs: Built-in relays let the PLC switch mains-powered devices directly, without extra boards or adapters.

- Integrated communication ports: Ethernet, RS485, and other standard industrial connections are available out of the box.

- Screw terminals and onboard power management: Secure connections and stable power make them ready for industrial environments.

Because of all these features, PLCs are usually expensive, putting them out of reach for smaller projects. That’s where the Arduino Opta stands out. It brings industrial-grade functionality to makers, engineers, and businesses at a much more accessible price point, bridging the gap between hobbyist microcontrollers and professional automation hardware.

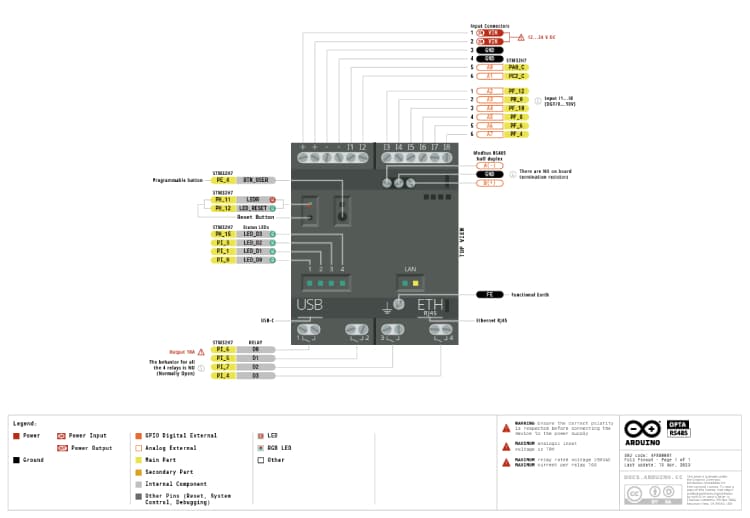

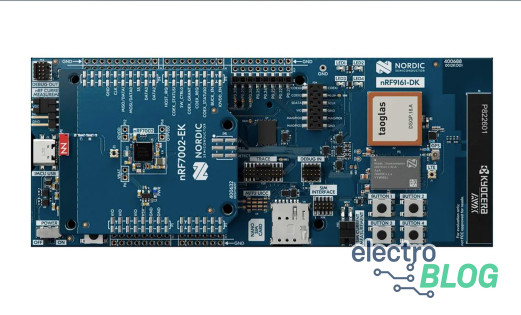

Meet the Arduino Opta PLC

The Arduino Opta brings the power of a professional-grade PLC into an affordable, compact form factor. Built around a dual-core microcontroller, it combines the flexibility of Arduino programming with the reliability demanded in industrial settings. This makes it equally attractive for engineers deploying automation systems and makers who want to experiment with real industrial hardware.

Here’s a closer look at what the Opta offers:

| Feature | Details |

|---|---|

| Processor | STM32H747XI dual-core MCU (Cortex-M7 + Cortex-M4, up to 600 MHz) |

| Inputs | 8 opto-isolated inputs supporting up to 10 V |

| Outputs | 4 relay outputs, each rated for 10 A |

| Connectivity | Ethernet, Modbus RS485, USB |

| Expandability | Side connector for DIN-rail expansion modules |

This combination of inputs, outputs, and communication options makes the Arduino Opta suitable for a wide range of automation and control tasks. It can switch heavy loads directly, monitor a variety of sensors, and integrate seamlessly with existing industrial systems. However, one key limitation remains: the Opta doesn’t include built-in wireless connectivity or native power outage detection. That’s where the Blues Wireless for Opta module steps in to complete the picture.

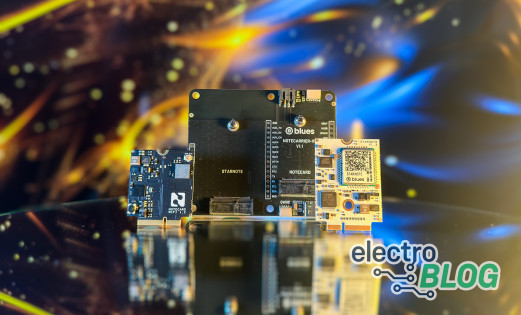

Wireless for Arduino Opta Explained

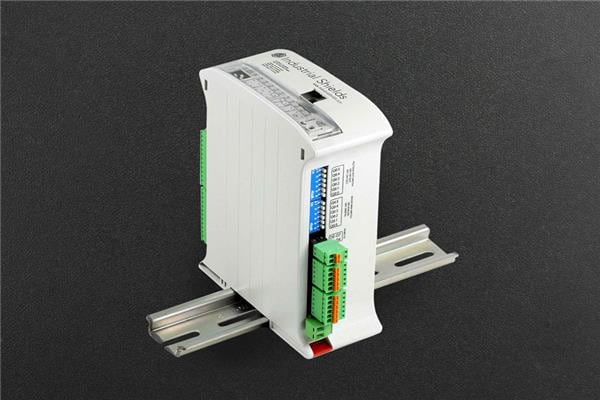

The Wireless for Arduino Opta is a plug-and-play expansion module that adds secure, reliable connectivity to the Opta PLC. Designed to attach directly via the side connector, it mounts neatly on a DIN rail and integrates seamlessly into existing setups.

What makes this module stand out is its dual-network capability. With both Wi-Fi and cellular connectivity, the Opta can stay online no matter what. If the local Wi-Fi network fails or isn’t available, the cellular fallback ensures that critical monitoring data and alerts are still sent. For industrial automation or remote monitoring, that reliability means no downtime and no blind spots.

Key features include:

- DIN-rail integration: Attaches directly to the Opta side connector for easy installation.

- Wide power compatibility: Operates from 12–24 V, fitting most industrial systems.

- External SIM slot: Use your own carrier, with 500 MB of free data included to get started.

- Outage detection: Integrated lithium capacitor allows the device to send one last alert if power is lost.

- USB-C port: Simplifies debugging and programming of the onboard Notecard.

Together, these features make the Blues module more than just a wireless add-on. It transforms the Opta into a cloud-ready, always-connected PLC, capable of keeping systems informed and controllable under any conditions.

Real World Demo: Smart Solar + Server Monitoring

To showcase what the Arduino Opta and Blues Wireless module can do together, a demo system was built around a home server setup powered by solar. The goal was simple: reduce energy costs, monitor system status, and keep everything under control even during power loss.

The setup included:

- Solar power: A large panel feeding a hybrid controller, backed by deep-cycle batteries and mains supply.

- PLC control: The Arduino Opta mounted on a DIN rail, connected to relays capable of switching 230 V loads like the server.

- Wireless link: The Blues Wireless module providing Wi-Fi connectivity, with cellular backup in case of an outage.

- Sensors: Flame detector, PIR motion sensor, and sound sensor feeding data into the Opta for real-time monitoring.

- Cloud dashboard: Data routed via Blues Notehub into Datacake, enabling visual dashboards and remote control features.

In practice, this meant the server could be power-cycled remotely, alerts could be sent if motion or fire was detected, and live sensor readings were always available. Wi-Fi handled normal communication, while cellular provided a final failsafe, sending an alert even if the main system went down.

Important note: this was a demonstration system only. The wiring shown in the demo was exposed and not suitable for permanent installation. In real-world applications, proper enclosures, cable routing, and safety practices are essential.

Developer Experience

One of the biggest strengths of the Blues Wireless for Arduino Opta is how easy it is to get started. Instead of juggling multiple libraries and complex drivers, everything revolves around a simple JSON-based interface. With just the Notehub library, developers can send and receive data without having to layer on endless dependencies.

In practice, this means you can:

- Read sensor data from the Opta and send it directly to the cloud.

- Use simple API routes to connect to services like Datacake for dashboards and controls.

- Integrate with major cloud platforms including Arduino IoT Cloud, AWS, Azure, GCP, and Snowflake.

For those just getting started, the workflow is straightforward: connect the module, use the Notehub library to push sensor values, and watch the data appear in your chosen cloud service. For more advanced projects, you can configure downlinks to send commands back to the Opta, allowing remote control of relays, actuators, or other connected devices.

Because the Opta is expandable and designed for industrial environments, you’re not limited to basic demos. You can start small with a few sensors and scale up into full industrial monitoring systems, all while keeping the development process simple and approachable. Whether you’re a seasoned engineer or a maker experimenting with PLCs for the first time, the experience is designed to get you productive fast.

Considerations & Limitations

While the Arduino Opta with Blues Wireless offers an impressive set of features, there are a few points to keep in mind before deploying it in real-world projects:

- Cellular coverage: The module comes with regional variants and 500 MB of free data, but performance depends on local carrier coverage. Check availability in your area before relying on cellular as a primary connection.

- Data usage costs: After the free allowance, cellular connectivity will incur ongoing costs. For high-frequency or data-heavy applications, Wi-Fi is the more economical choice.

- Environmental constraints: The demo system shown is illustrative. In real deployments, enclosures, proper cable routing, and environmental protection are essential for long-term reliability and safety.

- Safety practices: Switching mains loads and wiring sensors requires correct isolation and protection. Exposed wiring, as seen in demonstration setups, should never be used in production environments.

By understanding these limitations, developers and makers can plan ahead and ensure that their projects remain safe, reliable, and cost-effective.

Final Verdict

The Arduino Opta brings industrial-grade control into an affordable and flexible package, but on its own, it lacks the connectivity and monitoring features that many modern projects demand. With the addition of the Blues Wireless for Opta module, that gap is closed, turning the Opta into a cloud-ready, reliable, and fully deployable PLC solution.

Together, they provide a platform that is faster to bring online, secure in its communications, and reliable enough for both industrial environments and advanced maker projects. Whether you’re building predictive maintenance systems, monitoring solar installations, or managing a home lab, the combination of Opta and Blues Wireless makes it achievable without the overhead of traditional PLC systems.

What would you build with it? Share your ideas in the comments and join the conversation with makers and engineers exploring the future of connected automation.

Developer Resources

Ready to explore further? Here are some useful resources to help you get started with the Arduino Opta and Blues Wireless module:

- Blues Wireless for Arduino Opta – Product Page

- Arduino Opta – Official Documentation

- Blues Notehub – Developer Portal

- Datacake – IoT Dashboards and Cloud Platform

These platforms provide everything from hardware specs and setup guides to cloud routing tools and dashboards, giving you all the building blocks for your next automation project.

FAQs

Which platforms does Wireless for Opta support?

The module works directly with Arduino Opta PLC and integrates with Blues Notehub. It also routes data to cloud platforms like Arduino IoT Cloud, AWS, Azure, GCP, and Snowflake.

Does it support both Wi-Fi and cellular?

Yes. Wireless for Opta includes dual connectivity. It uses Wi-Fi when available, with cellular as a backup for uninterrupted communication.

Can I use my own SIM card?

Yes. The module has an external SIM slot for your provider of choice. It also comes with 500 MB of free data to help you get started.

Does it detect power outages?

Yes. An integrated lithium capacitor allows the module to send a final outage alert if power is lost, ensuring you’re always informed.

Is it suitable for industrial use?

Yes. It operates from 12–24 V, mounts directly on a DIN rail via the Opta side connector, and is designed for reliable performance in industrial environments.

Leave your feedback...