Revolutionizing 3D Printing: The Rise of Affordable Pellet Extruders

3D printing has rapidly evolved from a niche hobby to a cornerstone of modern manufacturing, enabling creators and engineers to bring their visions to life with unprecedented ease and precision. At the heart of this evolution lies continuous innovation, pushing the boundaries of what's possible within the realm of additive manufacturing. One such groundbreaking development comes from the workshop of Greenboy3D, who has taken a significant leap forward in making 3D printing more accessible and versatile.

Watch Ian talk about Greenboy3D's 3D printing machine in this episode of The Electromaker Show

Pellet extruders, traditionally used in industrial settings, represent a significant advancement in 3D printing technology, offering a more cost-effective and efficient method of material usage. However, their adoption has been limited by high costs, often running into thousands of dollars, making them impractical for hobbyists and small-scale creators. This is where Greenboy3D's innovative pellet extruder comes into play, promising to bridge the gap between industrial efficiency and home use affordability.

Unveiling the Pellet Extruder Revolution

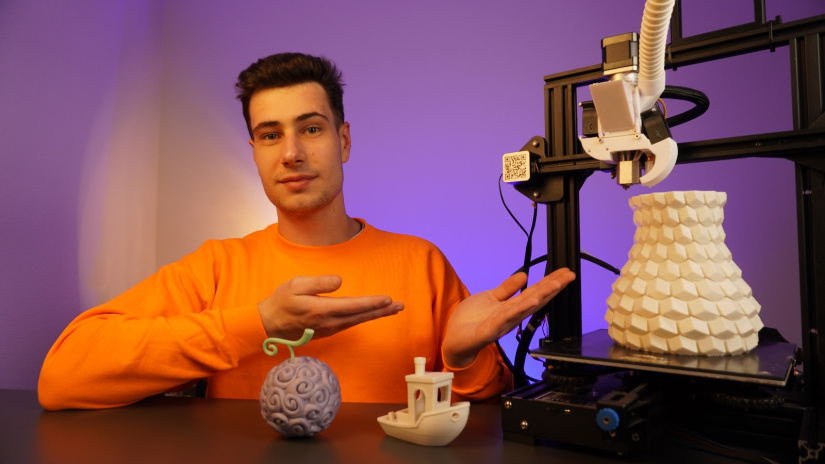

Greenboy3D has introduced a revolutionary pellet extruder capable of being retrofitted onto any existing 3D printer. This innovation is the culmination of two years of dedicated research and development, focusing on creating a solution that combines the high efficiency of pellet extrusion with the accessibility and versatility required for home use.

What sets this pellet extruder apart is its remarkable versatility. Capable of working with a wide range of materials—from traditional PLA to more unconventional choices like sugar and chocolate—this extruder broadens the horizons of 3D printing. Whether for creating intricate edible creations or experimenting with different types of bioplastics, Greenboy3D's extruder offers the flexibility and innovation that modern makers demand.

Environmental Impact and Cost Efficiency

The shift towards pelletized plastic in 3D printing, championed by Greenboy3D's innovative extruder, marks a significant stride towards sustainability and cost efficiency. By utilizing pellets instead of traditional spooled plastic, users can expect a dramatic reduction in printing costs. This cost-effectiveness stems from the lower price of pelletized materials and the extruder's ability to minimize waste, making high-quality 3D printing more accessible to a broader audience.

Beyond the financial savings, the environmental benefits of using pelletized plastic are equally compelling. Pellets offer a sustainable alternative by enabling the use of recycled materials, thereby reducing the overall plastic waste generated by 3D printing projects. This approach not only aligns with global efforts to combat plastic pollution but also empowers individuals to make environmentally conscious choices in their creative endeavors.

Technical Ingenuity and Community Contribution

The genius behind Greenboy3D's pellet extruder lies in its simplicity and effectiveness. By leveraging common parts and 3D-printed components, the extruder is not only cost-effective but also highly adaptable. This design philosophy ensures that the extruder can be easily integrated with a wide range of 3D printers, making it a versatile solution for enthusiasts and professionals alike. The use of readily available materials and parts underscores a commitment to DIY principles, fostering innovation and creativity within the 3D printing community.

Compatibility is at the core of this project, with the extruder designed to work seamlessly with existing 3D printers and firmware. This universal design approach ensures that users can upgrade their printers without the need for complex modifications or specialized knowledge, broadening the reach of advanced 3D printing technologies. By maintaining compatibility with popular firmware like Marlin, Greenboy3D ensures that users can continue to use their preferred software, making the transition to pellet printing as smooth as possible.

Central to the success of this project is the community-driven approach adopted by Greenboy3D. By actively seeking feedback and input through a dedicated survey, the project emphasizes the value of collective wisdom and user experience in refining and improving the extruder. This collaborative spirit not only enhances the final product but also strengthens the bond within the 3D printing community, encouraging a culture of sharing, learning, and mutual support. Participate in the survey and contribute to shaping the future of 3D printing.

Wrapping Up

By making pellet extrusion more accessible, it has the potential to transform how individuals and small businesses approach 3D printing, breaking down barriers related to cost and material limitations. The implications for creativity, sustainability, and innovation are profound, signaling a new era of growth and exploration in additive manufacturing.

Did you enjoy this article?

Make sure you subscribe to The Electromaker Show for similar content and subscribe to our monthly newsletter!

Leave your feedback...