CNC vs Professional Service – How should you get your PCBs?

Printed Circuit Boards (PCBs) are one of the best ways to take your maker projects to the next level. Their ability to hold soldered components, both through-hole and SMD, allows for the use of highly advanced parts, and their use of traces totally eliminates the need for wires. But should you use a CNC to make your own PCBs at home, or should you get your PCBs from a manufacturing service?

Introduction to PCBs

While PCBs from professional services such as PCBWay have only been available to makers for the past decade, makers have been making their own PCBs for decades. The photo etching method of making PCBs involves exposing a sensitized PCB to UV light with the PCB artwork placed on top which etched the image of the circuit into the PCB. From there, chemical processes remove the unneeded copper to reveal the final design.

Other makers who lacked access to photosensitive chemicals would use the toner transfer method whereby a laser printer is used to print a PCB pattern to a piece of photo paper which is then placed onto a copper clad board, ironed on, and the design transferred. This would then be etched to remove the areas of unneeded copper just like the photoetching method.

But another method that is largely popular exists which uses a CNC to mill areas of unwanted copper. Using a CNC to make PCBs has a long list of advantages and disadvantages, and so in this article, we will compare homemade CNC-made PCBs with professional PCBs from services such as PCBWay, and why you may want each one.

CNC PCB advantages

One of the biggest advantages of making PCBs on a CNC is that it can do so at great speed. An entire circuit can be designed from scratch, routed, milled on a CNC, populated, and tested all in one day. This means that designs can be developed extremely fast with daily iterations of a design possible. Small designs can be iterated so fast that by the end of the day there could be 5 changes to a small SMD circuit showing improvements with each design.

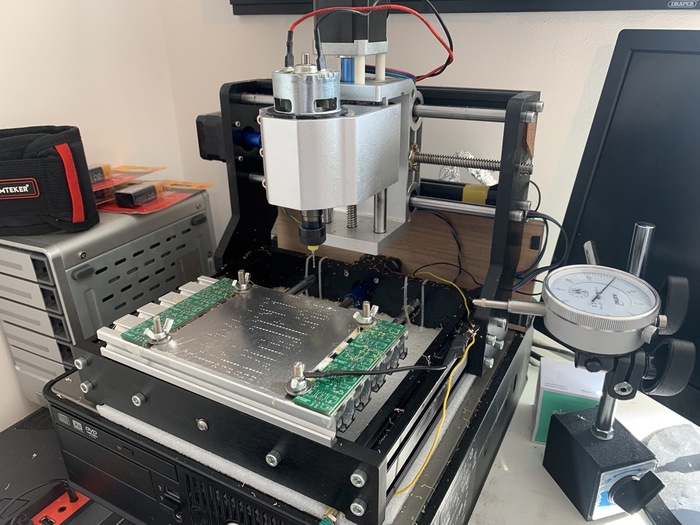

A typical CNC set up with a computer, runout tool, and sacrificial backplate

The second major advantage to CNC PCBs is that the cost to manufacture individual PCBs is very low when considering that there are no shipping fees, the price of copper clad, and the speed at which a PCB can be manufactured at home. The price of homemade PCBs also makes them ideal for quickly prototyping ideas before getting them professionally manufactured.

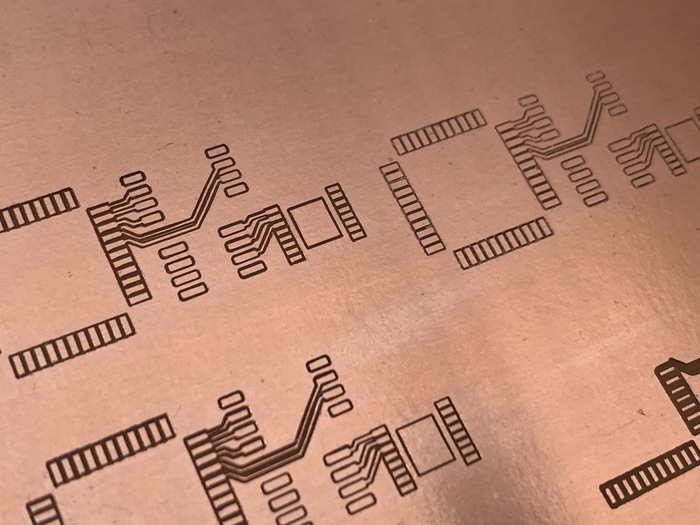

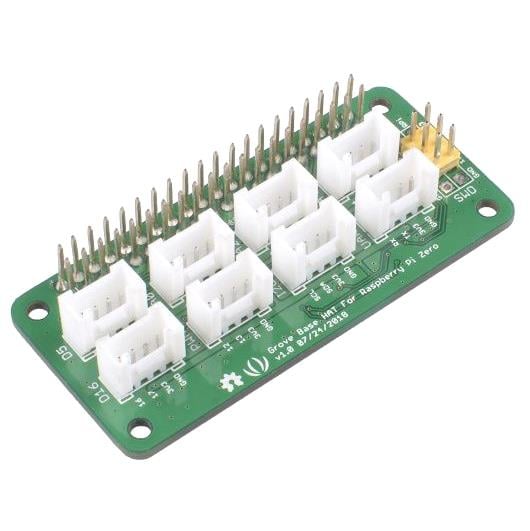

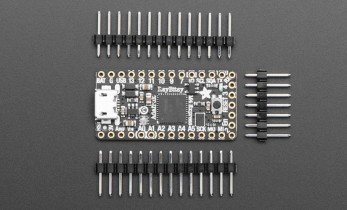

The third major advantage to making PCBs is that SMD components can be easily used which cannot otherwise be used in breadboard and stripboard projects. If a CNC is configured correctly using the right bits, it can be used to mill TQFP packages which opens up maker projects to many powerful ICs.

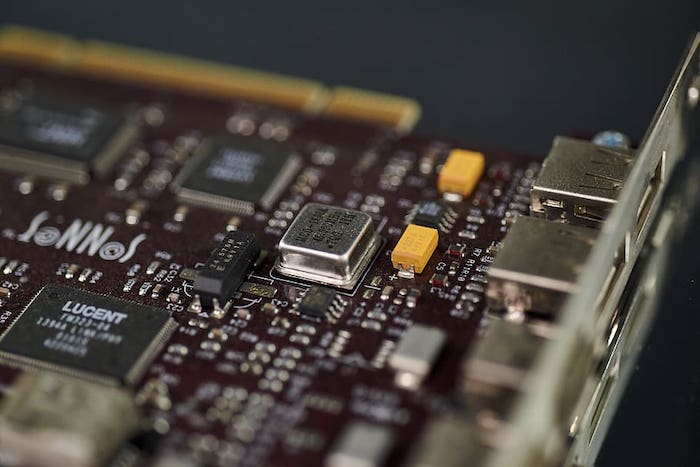

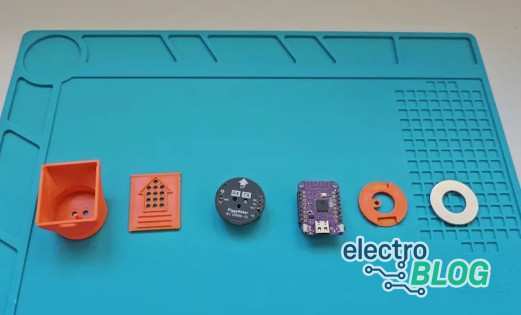

SMD components can be machined at home, but it takes great care!

CNC PCB disadvantages

While CNCs can be used to make PCBs rapidly, they often require intensive oversight during the milling stages. This can see a lot of labor, effort, and time is poured into the machine setup which could be better spent designing electronics or learning about new concepts.

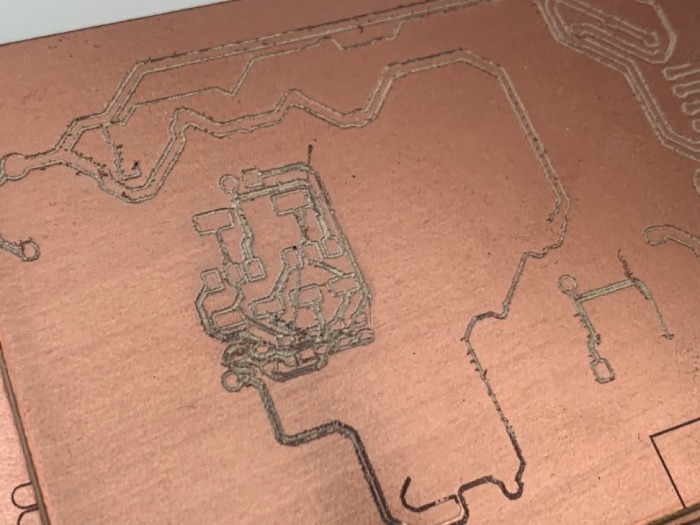

Another major challenge posed by CNCs is that making PCBs using a CNC is no small feat, and great care must go into ensuring that the setup provides precision and repeatability. If a CNC cannot offer a high degree of accuracy and has any drift or backlash in its axis, then the resulting PCBs may not be made correctly.

Poorly maintained CNC results in failed designs as shown here

Even though the price of CNCs continues to fall, they are still a large investment of several hundred dollars which can eat into a maker budget fast. This cost is more easily justified if the CNC is being used for more than just PCBs and be prepared to spend more money on the machine making improvements and spending hours configuring the hardware.

PCBs made at home on a CNC also suffer from a lack of important layers. Firstly, homemade PCBs don’t have more than two layers, and even then making more than one layer is extremely challenging. Secondly, homemade PCBs do not support solder masks and through-hole plating which are essential in any complex PCB design. Thus, homemade PCBs are generally limited to being a single-layer PCB with no solder mask or component legend.

Finally, trying to use SMD components on homemade PCBs can be extremely difficult when considering the precision needed by the engraving bit and the lack of a solder mask.

Professional PCB advantages

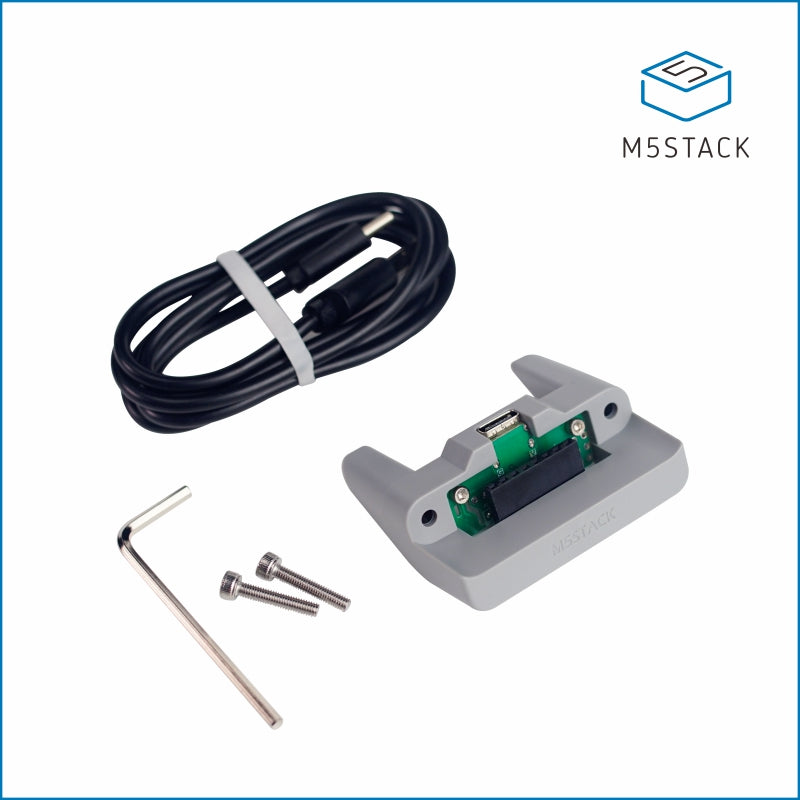

Professional PCBs purchased from manufacturers such as PCBWay have numerous advantages over homemade PCBs done using a CNC, and some disadvantages. To start, the biggest advantage by far is that a professional PCB has zero labor effort from a maker’s side. Gerber files are sent to the manufacturer who then fabricates your design for you, and their in-house testing system ensures that your PCBs come out perfect every time.

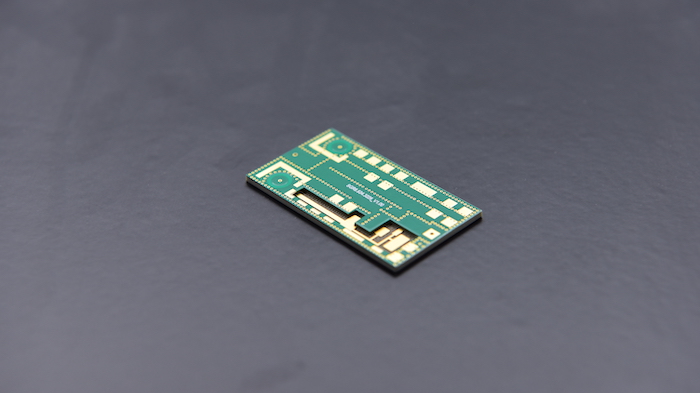

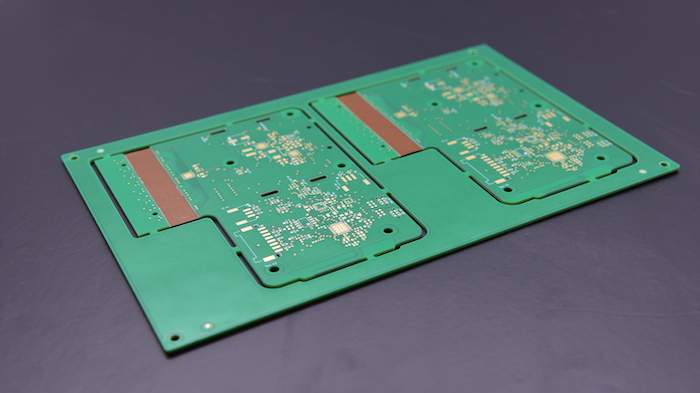

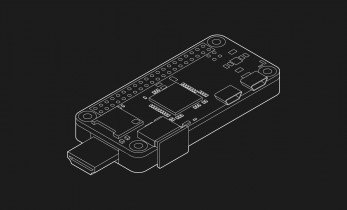

Professional PCBs purchased from manufacturers such as PCBWay have numerous advantages over homemade PCBs

The second biggest advantage of using a professional PCB is that they can be used in just about any application for any circuit you can think of. It doesn’t matter if a circuit is a simple 555 timer, or a motherboard with differential signals, either can be made using professional PCBs. This also means that they can be used with any SMD footprint on the market, and thus opens up your design to every component that you can get your hands on.

The third advantage to professional PCBs is that they can include multiple copper layers, come with solder masks and component legends, and have plated through holes. This means that they are easy to use, can include graphics and informative text, and require no wires or jumpers.

A fourth point to using professional PCBs, and this is a big one, is that they can be used with pick and place services that will also populate your PCB and solder it. Such services are becoming available to makers which means that makers no longer need to build their circuits. Furthermore, this also opens up makers to an extremely small component including those smaller than 0603 and MFL.

Professional PCBs can include multiple copper layers, come with solder masks & component legends

Professional PCB disadvantages

Even if a PCB manufacturer is next-door to your workshop, it will still take time to manufacture your boards and ship them to you. This means that you can expect to be waiting for at least a week for PCBs to arrive. While this is not a problem for large orders being sold on, it can be time-consuming for maker projects where only a single PCB is needed.

The second disadvantage to using professional PCB services is that any changes in a design take a long time to reflect in new PCBs. While homemade PCBs can change their design on the fly, it is virtually impossible to ask a manufacturer to halt the production of a batch of PCBs. This then leads us to the third disadvantage of professional PCB services which is that mistakes are expensive. This is especially true for those using pick and place services that build your design for you.

So, which one should you pick?

The best solution is to actually deploy both methods in your design as CNCs can be used to quickly prototype designs and test circuits while professional services, can be used to create the final design. But if you have no choice but to choose, it really comes down to two points; if you have the money and want to also own a CNC then using a CNC is a good idea, but if you are limited on space and just need to get a few PCBs a year, then go for PCBWay, all the way.

Leave your feedback...