Anycubic Vyper 3D Printer Review

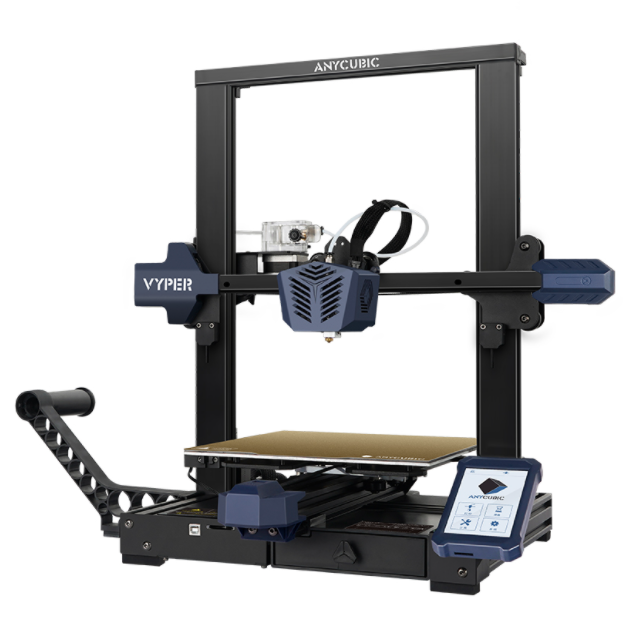

The Vyper is Anycubic’s latest challenger for the Ender 3-like category of printer and seems like a worthy opponent. With a variety of advanced features and components, it seems like a printer that’s both easy to use and cutting edge, but will its impressive feature set translate into performance?

Anycubic Vyper - Verdict

As a mid-range 3D printer with a large build volume, an array of quality of life features, and minimal setup all at a budget price, the Vyper exists within a very busy section of the 3D printer market, as just about every manufacturer has released one or two models competing for sales in this category, which can make choosing between them very hard.

Despite its difficult position, the Vyper compares quite flatteringly to its many competitors, making it a valid option and a worthy consideration. Unfortunately, there are a few minor drawbacks that prevent it from being at the top of its field, but not enough to let it be so easily discarded.

Visually the machine is obviously similar to the tried and tested design with a y-axis build plate, z-axis double rail, and belt-driven x-axis print head. Some of the more notable items are the blue plastic covers and integrated tool drawer which add some quality to the build. Finally, with a touch-screen and removable print bed, the machine has user experience in mind even from a first glance.

With a basic metal frame and some plastic housing and accessories, the machine certainly seems sturdy, with enough weight to not violently shake during quick movements. Speaking of quick movements, the motors on this printer are shockingly quiet, which would be incredible if not for the double fans that more than make up for that noise deficit.

The magnetic print bed is such a useful feature that any printer without it feels difficult and disappointing. The Vypers print bed, however, despite being magnetic spring steel that makes print removal easy, is covered in a rough coating that not only affects the quality of any first layers but comes away if you ever have to take a scraper to it for a stubborn model. While these issues are easily fixed with the use of a raft, that does tie you down to use a raft on every print, which may not be ideal for your project.

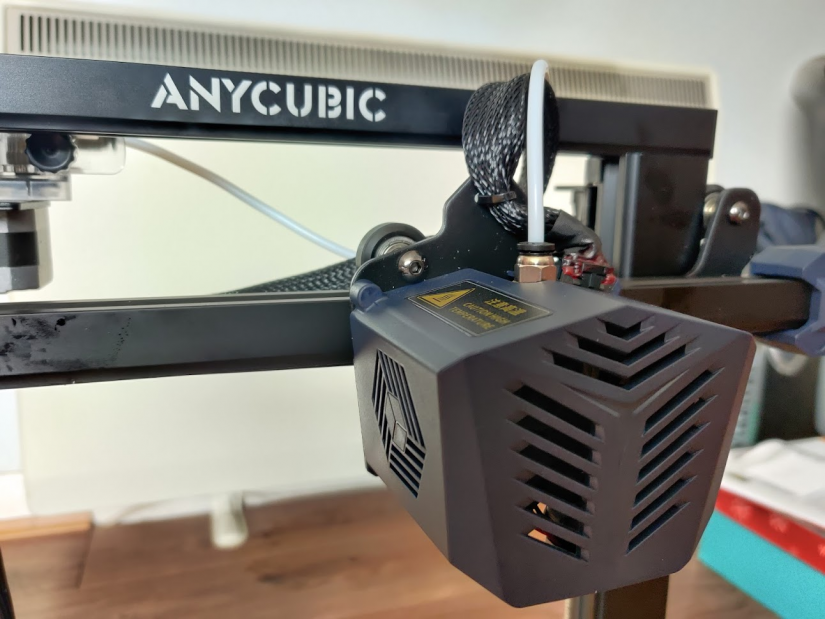

In use, the Vyper does start to show some mild oversights and drawbacks, notably the cable connected to the print head is positioned in such a way that it drapes along the print area, potentially non adhering models from the bed and failing a print. When loading a model onto the printer, you’ll also need to make sure that the G-code is in the root of your SD card, as the onboard software has no way of venturing deeper into folders. This small omission doesn’t make it a bad printer by any means but is a great example of the lack of care and attention this printer has been given to make it a truly great machine.

Pros

- Affordable price

- Large print area

- True auto-levelling

- On-the-fly print setting tweaks

Cons

- No printer profile on cura, supplied profile is suboptimal

- Poor print bed coating

- Software and Design oversights

Assembly and configuration

Putting the Vyper together is definitely a two-person job, with heavy build material and large size you’ll definitely want someone to hold it while you attach the frame to the base. Beyond that, however, there really isn’t anything else to put together, the unit ships assembled and aside from some packaging and safety zip ties it’s good to go.

The printer setup is also shockingly easy, the auto-levelling literally only requires you to press go and let it do its thing. This software-based levelling does take away finer controls for people wanting to tweak their setup or even account for adhesion changes, but a vast majority of users won’t ever need to consider these things, as the levelling the machine does is perfectly fine.

Setting up prints, however, becomes a little bit of a problem. Without any default options for the printer baked into cura, you will need to do some setup, which can be challenging for users not used to the software, and using the wrong settings could permanently damage your machine. The cura profile that ships on the SD card is also not the best you can use for the printer, and there are many alternatives online that make use of better settings, but your best option is to find the print variables that suit your filament and model on the fly.

Features

None of the features on the Anycubic Vyper feel gimmicky or tacky, everything chosen for it is sensible and useful...

Auto Levelling

As mentioned previously, this printer uses software-based auto-levelling which ensures the nozzle is always the right distance away from the bed. Without any physical controls for the bed height, the printer works out how high the print head should be at each part of the bed. Not only is this incredibly quick and easy for first time setup, but takes the headache out of needing to re-level the machine should you run into any trouble.

Filament Runout Detection

Thanks to a sensor at the beginning of the filament line, the printer can detect when there’s no filament left to print with and will stop in its tracks until it’s changed. Unfortunately, this really does cause it to stop in its tracks, without lifting the nozzle off of the model and often creating a blob of melted plastic and possibly even damaging the model if it happens on a fine detail. There’s also no way to disable this, so if your sensor was damaged or faulty, then you will absolutely need a replacement to keep using the printer, else it will pause printing intermittently, or worse, not start at all. This is just another software oversight that could have easily improved the quality of the machine.

Resume Print

As all good printers should, the Vyper will remember where it was should your printer lose power during a print, and will give you the option to resume. Whether you use this to pause printing overnight in a bedroom or to prevent failed prints on large scale production, this feature is an absolute must-have.

Dual Everything!

The Vyper doesn’t seem to do anything by halves, and these small things make it a reliable and quality printing machine. With dual cooling fans, printing areas in midair is much cleaner as the plastic becomes rigid very quickly. Double screw shafts along the z-axis make it incredibly precise and sturdy, and the double photoelectric limit switches mean z-axis zeroing is perfect every time, so you can trust the accuracy of even taller prints every time. Finally, the dual gear extrusion is perfect for feeding filament along the bowden tube, as they’re strong enough to force even flexible filaments into the print head.

Test Prints

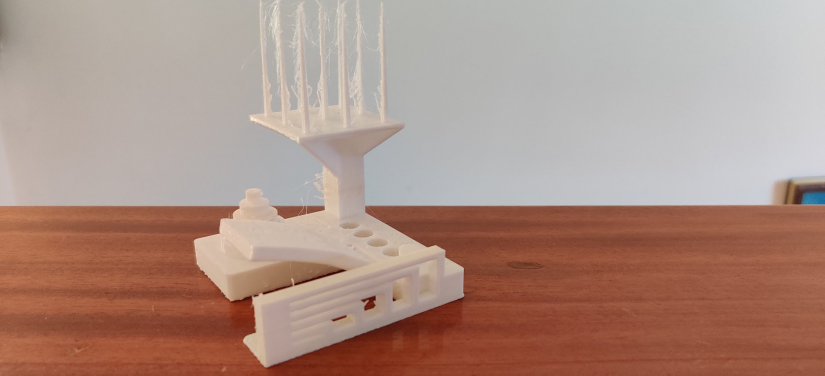

Provided Model

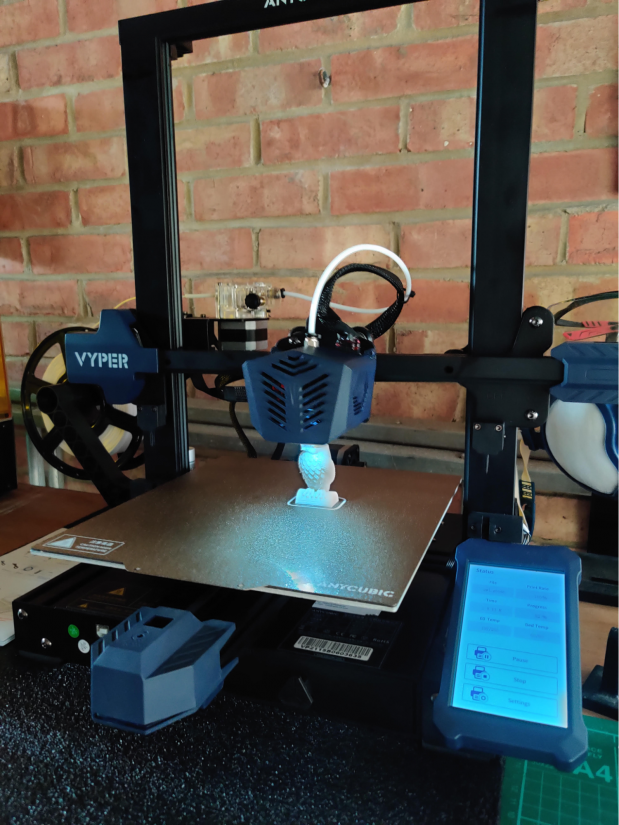

The printer ships with a ready-made g.code file for a basic owl model. While not much of a display of the printer's ability, this makes for a decent benchmarking test with some finer details, sharp points, and a simple shape. It’s definitely worth getting to print after basic setup, if not just to check everything is in order, the model makes for a good toy.

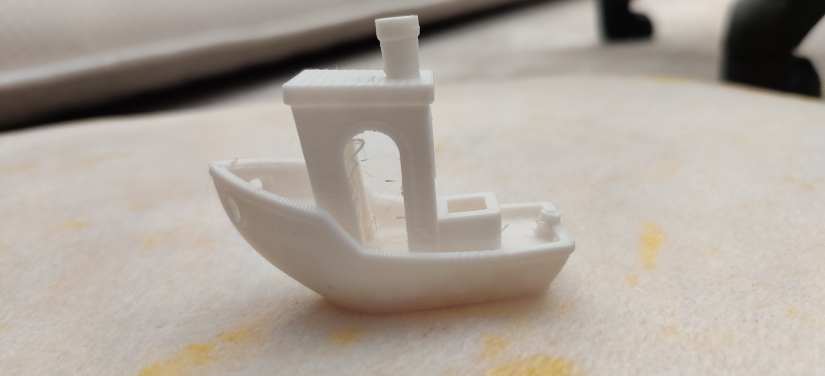

Benchy

The classic 3D printer “torture test”, Benchy the Benchmarking Boat is a popular first print for a new printer and tests the capabilities of the machine. The results of this are quite varied, the overhanging areas have printed perfectly, the dual fans seem to cool the plastic quickly enough to handle harsh overhangs like the window and doorway. Unfortunately, any detail on the bottom was lost from the poor quality print surface, and an odd rough texture was left on the base.

Autodesk Kickstarter test

As a benchmarking model, this one covers all bases and provides a score for each category based on easy to measure tests. The Vyper’s default settings didn’t do badly at all with this, but some tweaks could easily see these standards raised. That being said, the Vyper scores an incredibly competitive score from this test, its combination of high-quality components and well-tuned community cura profile showing their worth.

Dimensional Accuracy: 5 of 5 points

Fine Flow Control: 2.5 of 5 points

Fine Negative Features: 4 of 5 points (all pins were removable by hand)

Overhangs: 4 of 5 points

Bridging: 5 of 5 points

XY Resonance: 2.5 of 2.5 points

Z-Axis Alignment: 2.5 of 2.5 points

Total: 25.5

Vader’s Lightsaber

Printed in a few different parts and assembled, this replica of Darth Vader’s classic Lightsaber shows some great details and clean surfaces. It also tests the clearances for some push-fit assembly, which did need some light attention with a Dremel to fit, but this could be a model issue.

Loki’s Horns

In a stunning gold filament, this headpiece is printed in just 3 parts with minimal supports needed. The large surface areas of the curves and flats all show that the print quality is incredibly consistent and perfectly smooth in all the right places.

Lithophane Set

A set of Lithophanes show just how good the detail-work on this printer can be, under normal light they look like bad plastic versions of images, but with the right backlight the thinner areas of the print let through light, creating a gorgeous semi-3d grayscale photograph that makes for an amazing gift. As you can see, even the dog’s fur colouring is mimicked in incredible detail by the printer’s attention to layer thickness.

Technical specs

The Vypers specs are not to be scoffed at, with some great speeds and low tolerances, you can really push this printer to its most detailed and quickest print time extremes. With its volcano hot end, you can even swap out the print head for a wider nozzle bought separately and get some crazy quick large prints without worrying about the print-head heat bottlenecking your results.

Anycubic Vyper Specs:

● Printing Technology: FDM (Fused Deposition Modeling)

● Build Volume: 245mm(L)×245(W)×260mm(H)

● Print resolution : ±0.1mm

● Positioning accuracy: X/Y 0.0125mm; Z 0.002mm

● Extruder number: Single; Nozzle diameter: 0.4 mm

● Print Speed: <180mm/s (recommended 80-100mm/s)

● Support filaments: PLA, TPU, ABS, PETG, Wood

● Ambient Operating Temperature: 8°C - 40°C

● Operational Nozzle Temperature: max ≤260°C

● Operational Hot Bed Temperature: max ≤110°C

● Slicing Software: Cura; Output Formats: GCode

● Input Formats: .STL, .OBJ, .AMF

● Connection mode: Trans-flash Card; USB cable(expert users only)

● Input voltage: 100V/240V AC, 60/50Hz

● Output voltage: 24V/14.6A(350W)

● Machine size: 508mm×457mm×516mm

● Package Weight: Machine weight: ~10kg

Electroscore: 4/5

Value for Money - 4.5/5

This printer is incredibly cheap for what it’s capable of and definitely makes a good everyday printer for someone with some experience with 3D printing.

Features - 4/5

The features the Vyper boasts make it an incredibly robust machine with some very decent quality, but it does suffer from some unfortunate oversights.

Print Quality - 4.5/5

Evidently, the Vyper can produce some very high-quality models with some fine-tuning of the settings.

Software - 3/5

The onboard software isn’t bad, especially when you could benefit from tweaking your in-progress print settings, but with a lack of thought and care put into the options, it leaves some things to be desired.

User Friendliness - 4/5

The touchscreen and easy setup on this printer make it a joy to use, the only let-down is how treacherous and off-putting the Cura setup can be.

Final Thoughts

The Vyper might not be the best in class, but this printer should be a genuine consideration for anyone wanting a grown-up hobbyist machine. Experience with Cura and print-settings will make this machine an incredibly viable option and its results speak for themselves.

Leave your feedback...