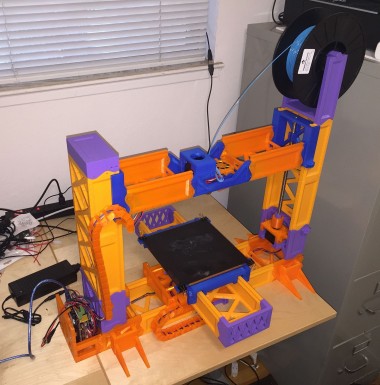

New Raprep 3d Printer

About the project

Hello, I am planning to develop a new 3d printer based on one of the existing Raprep designs. I want to make this printer as replicable as possible, with largest percentage of all parts 3d printed. I already have experience in 3d printing using Ender 3 V2, soldering and programming. I am 4th year computer engineering student.

Project info

Difficulty: Difficult

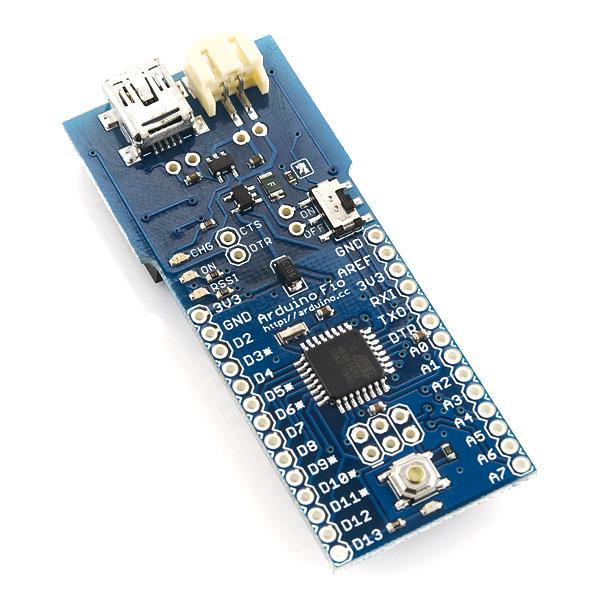

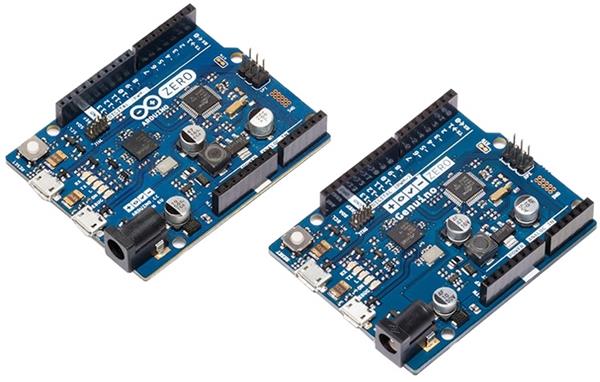

Platforms: Arduino, Raspberry Pi, Ender, Prusa

Estimated time: 1 month

License: GNU General Public License, version 3 or later (GPL3+)

Items used in this project

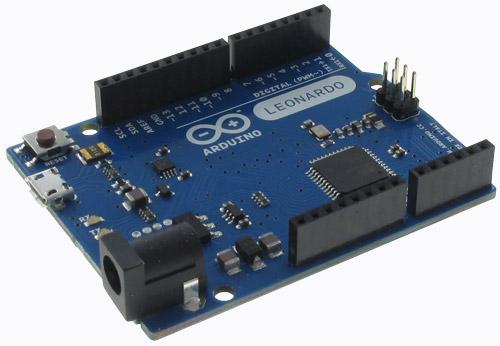

Hardware components

View all

Story

I always wanted to build a self replicating 3d printer. Unfortunately we are limited by material properties. For example you cannot 3d print nozzle using regular plastic, since it will melt at the same temperature as plastic it is extruding. But there are methods of going around this, like quenching, annealing, or curing(for resin 3d printers), which may allow this to be possible, at least in theory. Also stepper motors can be 3d printed using special magnetic and conducting filaments, there was some researches for the last couple years, but existing designs produce too much heat and melt too quickly to be useful for today. Now, the only major remaining part which cannot be printed remains the logic board and stepper drivers. Yet there already is some research going on about the 3d printing of the semiconductors.

I believe that everything can be printed including the 3d printer itself once you can use only 5 filaments: Mechanical dielectric filament such as PLA plastic, conducting filament, magnetic filament, filament for annealing (some progress is already done), and semiconductor filament (early stages of research for the last 2 years).

The person who can find out how to print using all the 5 filaments using a single device can open a door for a scalable, cheap manufacturing of day to day products.

And I need to build this 2nd 3d printer as a platform for my experiments. Later the first thing I will be trying do is to try using 3d printed motors in this design.

Leave your feedback...