Giant Board For Smart Iot Gateway In Drying System

About the project

Smart IoT Gateway could be used to collect the environmental condition in the drying system for an agricultural use cases.

Project info

Difficulty: Moderate

Platforms: Bosch, Microchip, Linux

Estimated time: 1 week

License: MIT license (MIT)

Items used in this project

Hardware components

Story

Introduction

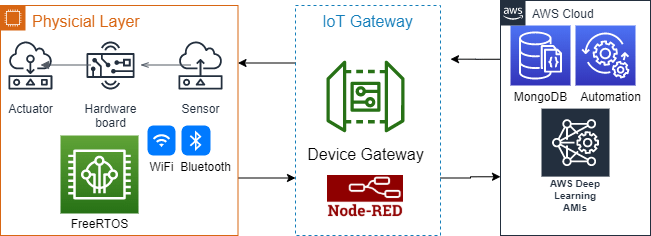

One IoT application is a monitoring and control system that connects sensors and actuators to an environment. Measurement data from the sensor can be sent to a cloud server so that it can be accessed by users who want to know a condition or measurement of physical quantities from that environment. The actuator can be controlled in response to the reading of the sensor values obtained from the environment. The important expectation of the system built from IoT is to run communication between the machine and other machines so that the system can provide accurate information. As a consequence, the system can become smarter in decision making. One of the things that are becoming popular now is the availability of increasing and inexpensive electronic hardware and software, for the purpose of building IoT infrastructure that allows it to be applied in many fields such as health, agriculture, industry, and transportation.

It is to design and implement Giant Board hardware as a broker, Bosch XDK as a sensor node and Node-RED software as a visualization of measurement data, and to send and receive data using Message Queue Telemetry Transport (MQTT) protocol.

This project is aimed to use MQTT protocol IoT with an Giant Board and Bosch XDK Sensors. It was made by programming with Eclipse IDE. We can send the data to the ThingsBoard cloud in real-time. The data can be visualized in ThingsBoard.

Problem

Indonesia is the world’s fourth-largest coffee producer and exporter. The arabica coffee beans market is a promising market in the future, especially when talking about specialty coffee. Low-quality coffee benchmarked by C prices, while specialty coffee is vague but many argue it strongly linked to the sheer quality. Poor prices caused by poor quality. Poor quality affected by many factors, one of the most important is processing. Coffee production consists of several phases.In general, there are harvesting or picking, processing, and milling. Processing, if done perfectly, could be an important value-added activity to improve coffee quality and so the price. Poor processing caused by traditional, trial, and error practices. No up to date technology or data utilization. Processing has various types, each of which can be distinguished from one to another based on the stage and type of treatment. But in the end, all types of processes have the same important stage, which is the drying stage. The drying stage is usually done in a greenhouse-alike (drying house) to optimize the process The drying process demands more attention and caution, as if the desired variables were not met, it could lead to various degraded products.

The quality of coffee beans at stake in the drying process is related to how long the coffee beans are dried. What is desired is a process of moisture reduction that is not extreme, with stable and consistent conditions. The traditional, trial, and error practices. No system of collecting and monitoring data for further utilization. The important variable that affects the drying stage is the temperature and humidity of the drying house.

Solution

Giant Board IoT Gateway collects temperature, humidity, and light intensity inside and outside of the coffee drying house. Then the data could be the basis for further treatment and/or practices to improve coffee beans quality. With the IoT, this can be overcome by the process of monitoring and access data from sensor networks.

We try to implement the Internet of Things (IoT) technology able to monitor every day on drying coffee beans. The duration of monitoring can be set as well as data the monitoring results are also directly connected and actually recorded on the database. So we hope this IoT technology can update the information on the drying process of their coffee beans. What is the subject of discussion in this project is how applying sensor technology through IoT to monitor physical quantities affect the quality of coffee beans, what is the relationship between environmental condition inside the greenhouse and outside greenhouse be modeled by statistical analysis, how it influences climate can affect the price and quality of coffee beans.

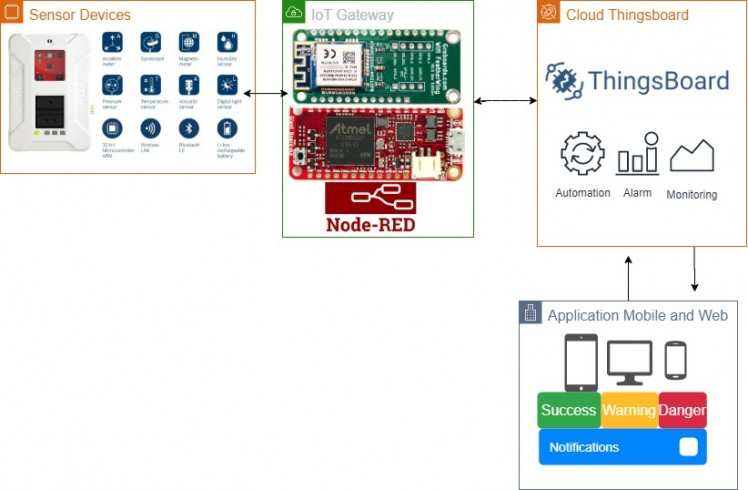

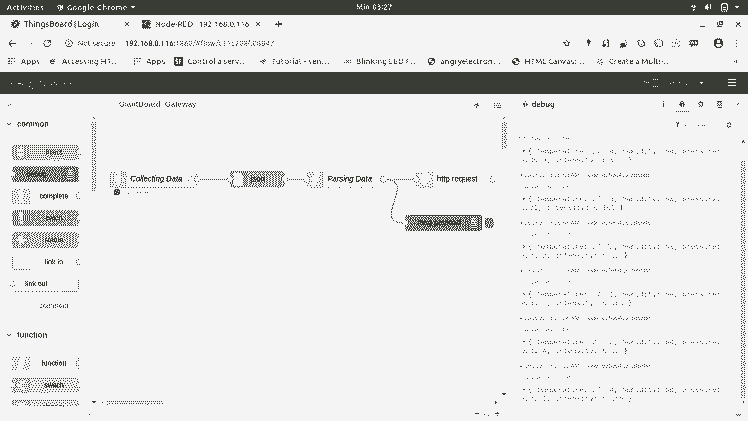

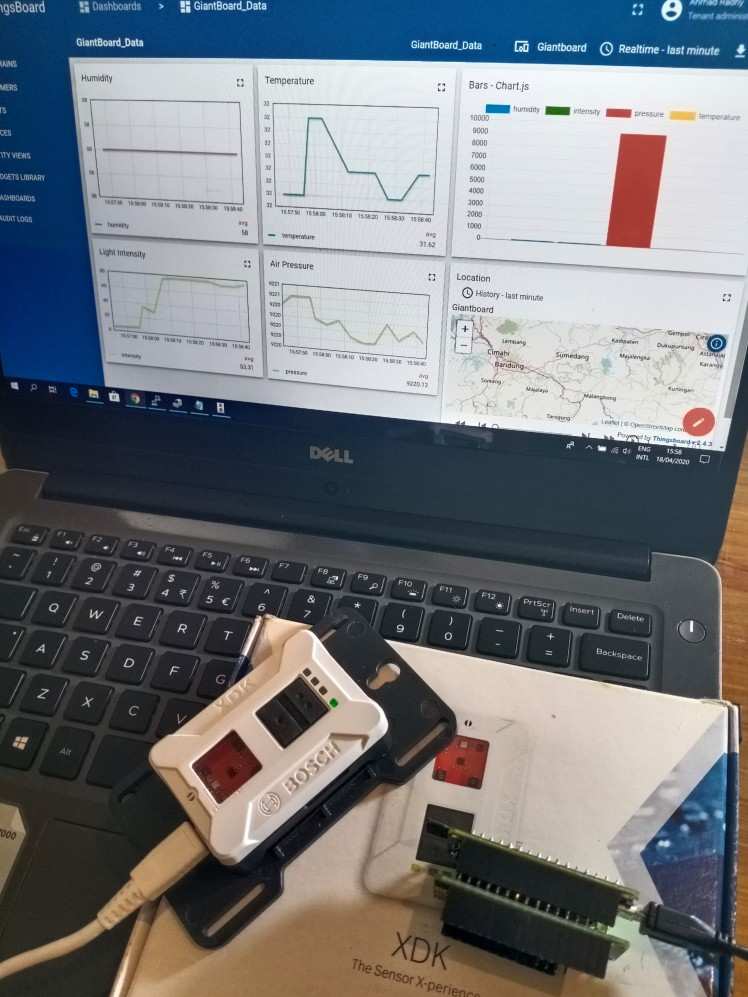

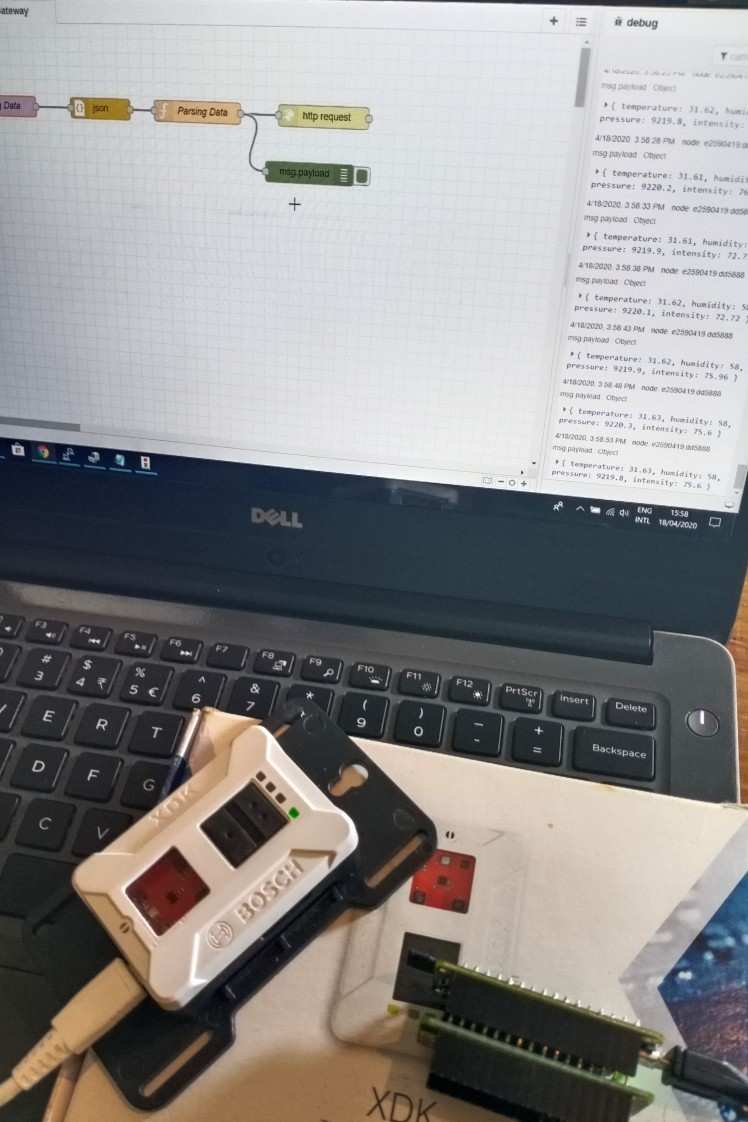

A network sensor system consisting of Bosch XDK and Giant Board IoT gateway Node-RED programmed in the Linux operating system (OS) on computers is used to collect air temperature data, air humidity, light intensity in the greenhouse. The data transmission sensor uses a communication protocol type Message Queuing Telemetry Transport (MQTT) to a gateway programmed using Node-RED.

By using the MQTT protocol, communication between Giant Board IoT Gateway and mobile apps or computers can be done wirelessly. Block diagram of data collection, consisting of 3 sensor pieces connected to the Bosch XDK called network sensors, Node-RED, cloud, local database, visualization, and computational modeling. Sensor data from the microcontroller is sent to the gateway.

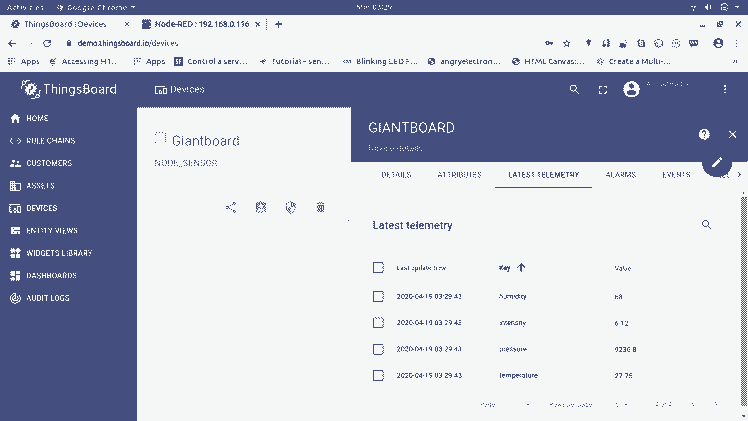

Then the data can be sent to the cloud and stored in the local database. Sensor data stored on the local database can be used for the visualization process in real-time on the Thingsboard cloud. To do computational modeling, sensor data can be accessed on the local database.

Real-time monitoring

It could provide reliable real-time data to the processor to monitor the drying stage of coffee beans. The goal is to improve quality by reducing the risk of undesirable conditions. The data could be used by the processor to plan and maintain the necessary treatment to ensure the desired conditions are met.

It also could act as a data collector for a microclimate condition and prediction in the future. By combining the data from various locations, the processed data could be used in wide variations of use, such as other plantation optimization and also risk and logistic calculation.

Implementation

Hardware

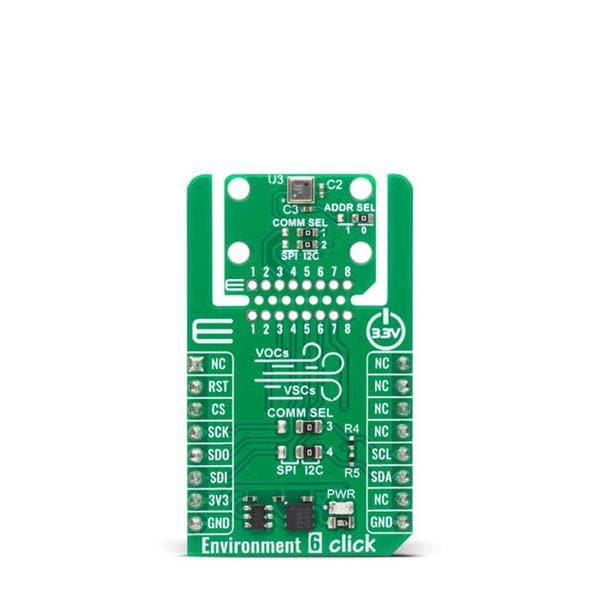

1. Bosch XDK Sensors (Temperature, Humidity, Pressure and Light Intensity)

2. Giant Board

3. Power Supply

Software

1. Node-RED (gateway)

2. Eclipse IDE

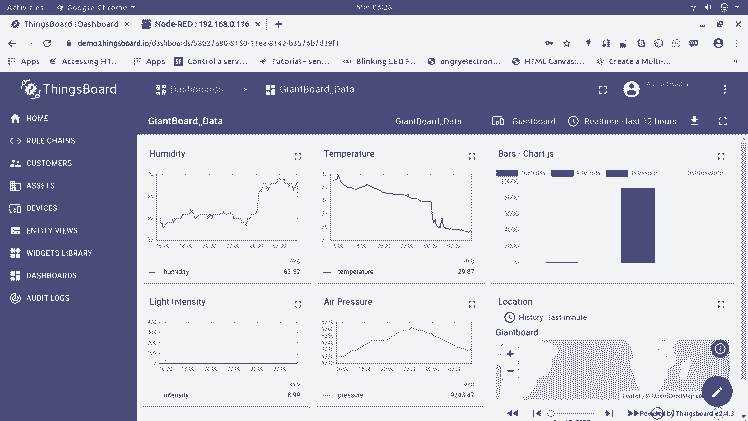

After testing the hardware which is the integration of the Bosch XDK sensor node and Giant Board microcontroller as the MQTT server, the visualization of measurement data is realized through the Node-RED dashboard. The implementation of the interface software design aims to display measurement data from both sensor nodes in real-time. There are 4 physical quantities visualized on the Thingsboard dashboard, including temperature, humidity, pressure, and light intensity.

The design of the data acquisition system using the MQTT protocol was successfully tested by integrating the Bosch XDK microcontroller as a sensor node and Giant Board as a broker. Scenarios from temperature and humidity, pressure, and light measurement as an implementation of the whole system has been successfully visualized using ThingsBoard. Bosch XDK measurement/payload data from Bosch XDK sensor nodes has been successfully stored in the ThingsBoard database.

Leave your feedback...