Smart Asphalt Road Using Nordic's Thingy 91 Dev Board

About the project

This project is for further development of a smart asphalt road for connected things high speed such as autonomous vehicles

Project info

Items used in this project

Hardware components

Story

Edge Computing is a term being used to define new way of managing IT resources and infrastructure by moving data selection, processing and analysis to a server placed at the edge of the internet, in closer proximity to mobile devices, if not the mobile device itself with the capability of sending and receiving data from sensors, and IoT devices. The edge refers to any IT infrastructure that serves both data sources and cloud data centers, meaning is not a static point or a place on a network but can be installed at a particular physical location of interest for a community or industry . Terms such as cloudlets, micro-data centers, and fog have been used in the literature to refer to these types of small edge-located computing hardware.

The edge is primarily set up to deliver low-latency data and support emerging applications such as augmented reality, live video transmission, connected and autonomous transportation, smart manufacturing, healthcare, and live data updates on demand. It functions as a place to store data, analyze, and provide results for devices that require a large bandwidth, as is the case for high-definition video camera

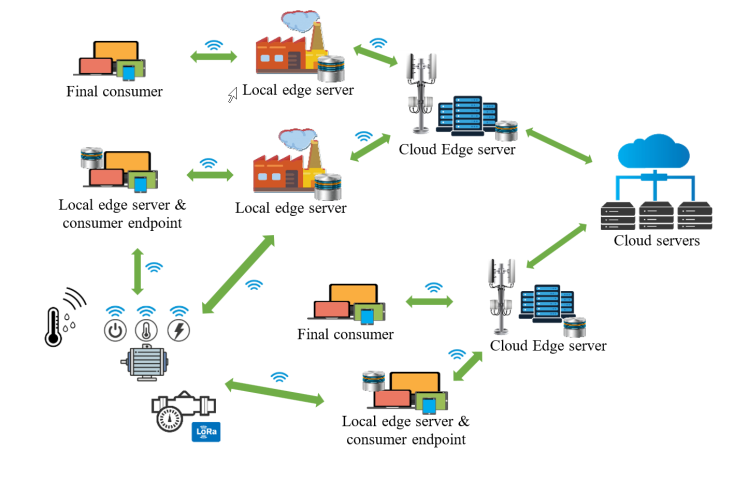

In Figure 1, it is schematically illustrated how edge computing serves as an intermediary of the data provider and data storage. Is possible to see end devices as simple data consumers and others also as data producers when needed. At the edge, data requests can be made to the cloud servers, requesting a service or cloud content, and at the same time act as a data provider, by performing the computational tasks requested from cloud servers. Edge devices can perform data processing offloading when performing partial analysis on the data they hold and serving results instead of the data itself. It also has the capability of data storage, caching, and distribute data requests depending on the nodes it connects at any given time to deliver services from the cloud to the endpoint device.

Figure 1 – Schematic representation of an edge computing network infrastructure

Edge computing's main advantage is to process a large amount of temporary data and upload only the necessary, greatly reducing network loads and bandwidth pressure, at the same time, saving processing CPU time on cloud servers. The fact that it is much closer to data producer devices means it can respond faster with lower latency times. At the end of edge, there are Internet of Things (IoT) devices and servers . IoT is a term used to describe physical objects commonly referred to as “things”: all kinds of electronics and materials with the ability to collect and serve as data acquisition devices for transmission over the internet. In the context of IoT applications, cloud computing architectures present the following challenges:

According to the International Data Corporation (IDC) forecasts, data growth will reach 175 zettabytes (ZB). Overall, 51,4% of the data will be generated by IoT devices and 30% of data will be for consumption in real-time by 2025. Part of IoT devices are sensors, software, and other technologies with the sole purpose of connecting and exchanging data with other devices and systems without human interaction.

Depending on the type of tasks the IoT device is set up to do, data it produces can be delivered to a local mobile device, acting as a local server (see figure 1), or instead connect to a nearby cellular tower using 4G/LTE, for data exchange and for data requests, processed using machine learning and artificial intelligence on the local edge server. This type of electronic device is characterized by having a lower power consumption and reduced physical dimensions. IoT devices do not infer reality nor limit or constrain it. Their purpose is one of collecting data and making it available with the ultimate goal of facilitating the life of a citizen. Potential applications, according to Patel et al., including all areas related to business such as the manufacturing sector, the health sector, agriculture, transport, smart cities, security & surveillance.

Network Structure

An important part when implementing a monitoring network for live data acquisition is the network structure, i.e., how smart devices connect and relay collected data back to the database where is stored in a server. The network-server is responsible for the management of the whole network. It knows about active smart devices and when a new one joins the network, performs some kind of authentication while verifying if the new smart device is allowed to join the network and if so, which settings to use.

There are several solutions available to select a medium to relay data to the network database, on the server. A monitoring network often includes intermediate devices, called gateways, that are able to forward data packets between smart devices and the network server. Examples of a gateway include Ethernet gateways, cellular gateways, and even LoraWAN gateways. A LoRaWAN network is a type of network solution that enables connectivity with battery powered smart devices (class A, B, or C) that broadcast their sensor values to all gateways in range which then forward data packets through the network to the edge server using a wired connection, or even using the cellular network UMTS/GPRS. Are most used for ultra-low powered smart devices that can last years on a single battery charge.

Carbon Fiber-Based Self-Sensing Composites

Self-sensing composites are a type of smart structural composites that are part of multifunctional structural materials with the ability to act as an IoT sensor and perform functions such as sensing strain (figure 6), stress, damage, or temperature. This type of composite materials has conductive properties with the particularity of change (output) when deformation is applied and, in a way, can be correlated with the deformation state (input) at any given moment in time. This electrical property enables this type of composite to behave as a sensor for IoT applications while performing the intended structural function designed for. Moreover, it enables the possibility of non-destructive and nonintrusive structural inspection, and more recently, these smart composites became cost-effective for being installed and integrated into a structural monitoring network for a remote request of its electrical resistance (R) output. This is allowing reading outputs at measurement points on the structural element for verification of serviceability status in a remote way, without requiring physical presence on site.

Figure 2– Carbon fibers utilized in this project

Research on R behavior of self-sensing carbon fiber polymer composites (SSCFPC) has shown sensing ability to vary as a function of the weight ratio of micro-carbon fibers in a composite (wt.%). Previous analysis by Miguel et al. on the results produced by the same experimental campaign this research paper is based has shown that for up to 13%, measurements were found to have a linear decreasing behavior when axial strain is applied. For composites with approximately five times shorter fibers and wt.% greater than 40%, was found to have linear increasing behavior.

Figure 3 – A simple visualization on how the setup may be put together

The typical response of a sensor can be classified as static, dynamic, linear, multilinear, nonlinear, among others, and according to the expected input-output behavior. To mitigate errors, it is possible to introduce some data processing strategies with the purpose of improving the estimation of the true value. To achieve this, it is necessary to include more parameters in the calibration model in a way that allows post-processing of raw measurements, obtained from self-sensing composite material, and corrections, improving the accuracy between input and output.

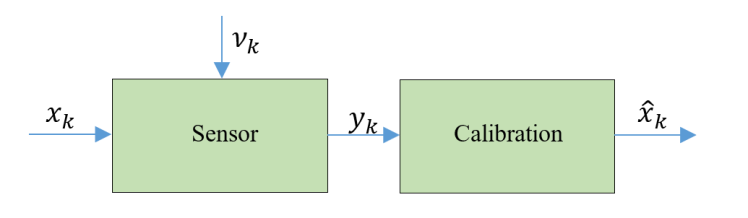

Figure 4 - A graphical description of Anas W. Alhashimi’s definition of the concept “sensor calibration”.

Anas W. Alhashimi defines a concept for sensor calibration, shown in Figure 4 in a simplistic schematic form, to determine the true value for the observed quantity ; is a random deviation to account for all systematic errors; is the sensor’s output and the final calibrated measurement.

There are two well-known industrial processes in which calibration of a sensor can be done. One of the industrial processes adds the calibration process into the production line to perform an initial calibration for each sensor being produced. During this process, the necessary electronic hardware is added to the sensor design for output correction. The second industrial process consists of manufacturing a sensor with a complete system-level calibration. This process includes electronics hardware with software capabilities that enable later customization and configuration according to specifications, improving the functionality and performance of the sensors produced. This research work is included in the latter.

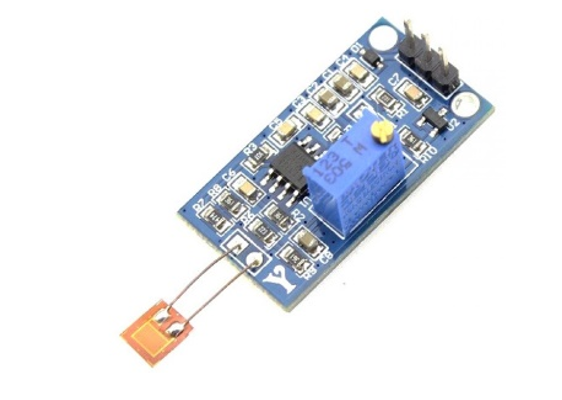

Figure 5 - Strain gauge module for Arduino applications with the strain gauge BF350-3AA

Previous studies focused on the possibility for carbon composite materials to act as stress and strain sensors and allowed the possibility of assessing damage due to fatigue or delamination by self-sensing damage measuring electric resistance, R, output state. Measurements of R on polymers incorporating micro carbon fibers, submitted to uniaxial tensile strain loading and subsequent unloading were found to have sensing ability for mixtures with 10% volume of micro carbon fiber; strain up to 7% and stress up to 0,40MPa.

Research on the effects of R in micro carbon reinforced polymers (MCFPC) led to the conclusion that this type of sensing ability can present negative or positive R according to the weight ratio of micro carbon fibers in the composite. Smart materials enable the possibility, through an adequate observation of loadings on monitored structural elements, to correct, when necessary, eventual anomalies that might appear during its life cycle. This becomes especially relevant when dealing with carbon fiber composites in high tech industries such as aerospace and automotive industries where maintenance and continuous serviceability status is required as high standards of durability and safety.

The capability of this type of composites act also as stress/strain sensor, opened the possibility of real time monitoring on such type of structural elements. However, carbon fibers composites as any other material does present its limitations when dealing with fatigue or failure . Delamination, matrix cracking or other types of fatigue might occur on said composites and be difficult to detect or monitor during its service life, mainly, because damage is not easily visible from an outside inspection.

Previous studies also demonstrated the possibility of carbon fibers laminates itself act as sensing of stress and strain and differentiate from those with self-sensing ability of damage . Although both can be achieved using carbon fiber polymer-matrix composites by means of resistivity measurements. Wang X. et al studied sensing ability during delamination in carbon fiber reinforced polymers (CFRP) during fatigue by means of resistivity measurements and successfully demonstrated an increase of irreversible nature at 33% fatigue life of CFRP, it is also noted electrical resistance, R, increase upon loading and subsequent decrease upon unloading on every cycle indicating strain sensing capability of composites in analysis.

Structural monitoring has nowadays high costs due to materials and equipment used and requires need of specialized labour upon application. Carbon fiber polymer matrix composites containing short carbon fibers, present effective strain sensing capabilities due to composite’s piezoresistivity nature. Said piezoresistivity is not only due to electrical conductivity of carbon fibers within composite matrix but also due to change in proximity between adjacent fibers when submitted to strain. Sara Cravanzola characterized multiwalled carbon nanotubes. L. Wang demonstrated piezo effect with carbon nanotubes and studied tunnelling effects of conductive paths on composites at study. Timothy M. et al demonstrated improved results on micro carbon reinforced composites (MCRP) incorporating nickel nano-particles improving sensing capabilities for low values of strain.

Figure 6 – First measurements of sensing capabilities using a multimeter

2 - Artificial neural networks for IoT Applications

Artificial intelligence (AI) and machine learning (ML) are the next step in self-sensing materials toward smartization an integral part of the ongoing 4.0 (fourth) Industrial Revolution. Today, AI and ML technologies can be found in a wide variety of fields of knowledge, such as computational mechanics structural engineering environmental engineering, materials science, and earth sciences. To name a few. Some of the factors driving this change include the increased complexity of algorithms and learning models with the growth of computing power per watt and the availability of data.

Data analysis was until recently implemented at the industrial process control level, moving statistical modeling tasks to centralized servers where results were stored. This type of system design and architecture could only perform data modeling up to a threshold, limited by the physical hardware resources available. The exponential growth on stored data increased the minimum requirements in hardware, and this led to the possibility of implementation of new approaches to doing data analytics. AI and ML modeling enable us to overcome the data size limit while taking advantage of increased computational power and provide statistical tools for multidimensional patterning, classification, and clustering.

In the specific area of self-sensing carbon fiber composites, ML tasks can assist in the quality of measured data with the identification of a fingerprint for a specific self-sensing composite element in a structure. These semi-automated or even fully automated tasks are of great importance when dealing with real-time, live, data monitoring environments, such as the case of standardization on an industrial manufacturing plant. Moreover, are proven to provide an edge that facilitates a faster transfer of a laboratory idea to industrial production and applications; allow one to perform real-time characterization for fault/anomaly detection and do component benchmarking .

Many research studies have been published using AI technologies. Luisa Völtz et al. utilized artificial intelligence algorithms to study carbon fiber damage in epoxy composites. Georgios Konstantopoulos et al. presented a study on “nanoindentation mapping data processed with machine learning classification models to identify interfacial reinforcement in carbon fiber composites”. Daniel Sammons et al. researched the use of convolutional neural networks for the non-destructive evaluation of delamination in carbon fiber composites using image data obtained from X-ray computed tomography.

When looking for a model to describe a specific dataset there is no panacea. The best approach is to utilize semi-automated solutions with a wide range of ML algorithms available to assists in modeling real-world classification and regression tasks. An example of a classification algorithm is the decision tree algorithm. This work is related to regression tasks and therefore uses a model part of the known black-box models2, such as support vector machines (SVM) and artificial neural networks (ANN). This type of data modeling is able to identify unseen and complex patterns with higher accuracy than more traditional methods by using large datasets during the modeling process .

An ANN introduces the concept of adaptive weights to establish connections between (hidden) layers making this algorithm more suitable to digest huge amounts of data for best prediction metrics . Deep learning, also known as deep structured learning, is an ANN part of ML algorithms with learning capability. Multilayered feedforward backpropagation is a supervised learning algorithm frequently found when doing automation modeling of collected data, part of the deep learning algorithms available in ML.

Deep learning is a popular learning method because of its ability to be modeled on different network architectures, with excellent predictive performance, also because of the availability of ready-to-use libraries in many coding languages. Past research works on carbon materials using Deep Learning algorithms include “Characterizing fracture stress of defective graphene samples using shallow and deep artificial neural networks” and “deep learning approach for determining the chiral indices of carbon nanotubes from high-resolution transmission electron microscopy images” among many.

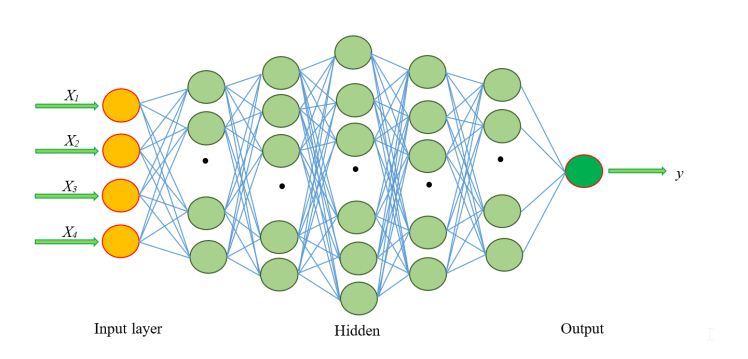

Training an ANN model on acquired data is subjective to patterns and observations that are identified on previous data collected, meaning that prediction efficiency is most likely to suffer in new data. As important, hyperparameter tuning is another key task during the modeling process and significantly affects predictive ability . This type of neural network algorithm uses a set of input values X and output values Y. The task of the neural network is to find the weights and biases on the network, according to the initial optimization parameters defined, minimizing the error between the actual output,, and the predicted output, using a function based on the delta rule. The precision of an ANN depends on the number of iterations, the network topology (number of layers and neurons), learning rate, the dropout rate among many other parameters according to studies and fields of knowledge.

To the best of the author’s knowledge, there are limited studies proposing ANN models to automate R calibration measurements in carbon fiber composites with self-sensing capability when undergoing an invariable deformation () for prolonged periods of time. Common evaluation indicators, such as the Pearson correlation coefficient (r), mean absolute error (MAE), mean square error (MSE) are used to evaluate the performance of proposed neural network architectures.

Figure 7 – Schematic of the architecture for the ANN

3 - Artificial Neural Network Model and Study Methodology

In an artificial neural network, an activation function, , is a non-linear transformation of input values required to allow the modeling of complex tasks. During the training process, a common performance function, such as the mean square error (MSE), is used to calculate the distance between the real and predicted data.

To improve generalization in the ANN model, a stochastic gradient-based optimization algorithm is preferred to minimize target values. Gradient descent is an optimization algorithm that optimizes the loss by updating the weights on the network nodes by an amount proportional to the negative of the gradient. The gradient is calculated using a process called backward propagation. First, the error contributed by each node is calculated by traversing backward from the output layer towards the input layer, adjusting the weights accordingly while reducing error across all layers. This optimization algorithm maintains a single learning rate hyperparameter for all weight updates across all network nodes and does not change during training.

Adam is an optimization algorithm that can be used instead of the classical stochastic gradient descent algorithm to update the network weights iteratively based on training data. The Adam algorithm computes individual adaptive learning rates for different parameters from estimates of the first and second momentum of the calculated gradients. Adam's optimization algorithm also uses the average of the second momentum of the gradients (uncentered variance). Specifically, the algorithm calculates an exponential moving average of the gradient and the squared gradient, and and parameters control the decay rates of moving averages determined in the process.

This algorithm provides a new set of weights for each iteration which are then used to calculate the prediction and the corresponding loss value. The entire process of forwarding propagation, backpropagation, and weight updates is an iterative process that continues until the loss of the network converges to a minimum value; when reached, the corresponding weights are optimal. A loss function in a neural network measures deviation of the estimated values from the experimental data values. A commonly used loss function is the mean squared error (MSE). The training process of an ANN algorithm can be defined as follows:

In this study, the effect of the number of iterations and the random sampling technique are investigated. Statistical indicators, including MSE, MAE, and r2, are calculated and analyzed to assist in the validation process of the model and the selection of network architecture.

4 - Database Collection and Preparation

The change in electrical resistance (R) can be explained by many factors, namely, carbon fiber content, length, and temperature of the surrounding environment. To model experimental data collected in the laboratory, the methodology followed consisted of three main steps. In the first step, data is taken from the laboratory test results prepared and aggregated into a common database. The input parameters for the ANN model are constant deformation time (X1), carbon fiber diameter to length ratio (X2), fiber volume fraction (X3), and environment temperature (X4). The output (Y) for the input parameters to be modeled is the relative amplitude of the electrical resistance,. To model experimental data is randomly divided into two sub-datasets using a uniform distribution, of which 80% of the data is used for training of the ANN models and 20% of the remaining data is used for validating the model. Where needed, data will be scaled to a [0-1] range, to reduce the numerical error during ANN processing. The process ensures training phase of the ANN models can be performed with functional generalization capabilities.

5 - R Response due to an External Mechanical Load

The principle behind a resistive sensor can be explained with a conductive wire. When a traction force is applied, it starts to elongate its length, l, while its cross-section, A, decreases. Variations in electrical resistance, due to strain on a carbon fiber composite, are determined by the difference between the initial electrical resistance, and measured at deformation,

At present, the R behavior of SSCFPC when submitted to external load or deformation is fairly accepted. Previous research works focused mainly on analysis during triangular loading environments. Under such conditions, the results show that this type of carbon fiber construction as a sensor has good R agreement with strain deformation. However, little has been done testing R behavior when specimens are undergoing a prolonged period of time with constant strain deformation. It is known that the intrinsic viscoelastic properties of polymer-based materials include the creep phenomenon, and when it occurs, the embedded carbon fibers in the composite tend to be rearranged, altering the R behavior without a change in strain.

The stress relaxation effect is particularly important on the sensing ability of this type of self-sensing composites as the composite may not be constantly subjected to strain variation during operation, rather being in a state of constant strain for prolonged periods of time. Think for instance a setup where a sensor is to measure displacements at foundations in a concrete structure. Under such conditions, it is important to quantify R during long periods of unchanged (constant) strain.

6 - Viscoelastic response due to Temperature

Another parameter monitored during the experimental campaign was the ambient temperature to evaluate the influence of the external temperature load on the specimens during the R measurements. Previous works have found R of carbon fiber composites to be inversely correlated with temperature, a behavior also observed on semiconductors . This thermorheological behavior is important to understand because it influences the R behavior of this type of self-sensing composites.

The phenomenology of viscoelastic response due to temperature has been presented for many materials, namely, polymers with low melting points, and they tend to exhibit different substantial viscoelastic behavior at room temperature. For example, the works presented have found that the R of the carbon fiber composites studied is inversely correlated with its temperature. To account for variations in intrinsic viscosity of amorphous polymers as a function of temperature, it is possible to employ the principle of time-temperature superposition, combined with an empirical WLF equation (Williams, Landel, and Ferry, Furthermore, it is common to find definitions for a horizontal shift factor, to determine and evaluate a polymer composite to temperature.

7 - Viscoelastic response to constant strain

Currently, the R behavior of MCRP when subjected to external load or deformation is fairly accepted. However, previous research works focused mainly on the analysis during triangular loading environments. Under such conditions, the results show that this type of carbon fiber construction as a sensor has good R agreement with strain. However, little has been done testing R behavior when specimens are being submitted to a prolonged period of time at constant strain. It is known that the intrinsic viscoelastic properties of polymer-based material include the creep phenomenon, and when it occurs, the embedded carbon fibers of the composite tend to be rearranged, altering the R behavior, while the strain remains unchanged.

The stress relaxation effect is particularly important on the sensing capability of specimens as these may not be constantly subjected to strain variation, rather be in a state of constant strain for prolonged periods of time. Think for instance a setup where a sensor is to measure displacements of foundations in a concrete structure. Under such conditions, it is important to quantify R during long periods of unchanged (constant) strain.

8 - Viscoelastic response to time dependent strain deformation

Piezoresistivity in MCRP composites are characterized when resistivity changes in accordance with imposed strain, which translates into sensing ability by means of measurement of one another. Positive piezoresistivity sensing is defined by R increase with increased strain, whereas negative piezoresistivity translates sensing behaviour of a composite by decrease of R with increased strain. Moreover, is important to evaluate reversibility nature of R to define strain sensing from irreversible measurements or damage sensing.

9 - Objectives of this Project

This project objectives, consist on development of a smart asphalt road with sensing ability that is at same time low cost and easy deployment, not requiring specialized labour. Samples tested are composited with a non-conducting traditional asphalt matrix and conducting carbon fiber filler. When submitted to tension or compression loading, present change in resistivity. This change is related to imposed strain and thus deformation can be plotted as a function of measured .

Previous research focused on piezoresistivity behaviour of MCRP when submitted to time changing stress / strain loading. Wang and Chung, Todoroki and Yoshida and Xiaoping S., investigated piezoresistance of MCRP composites when submitted to compressive loading. Park et al proposed a model to describe change in electric resistance in fiber direction taking account fiber breakage due to tensile strain.

10 - Experimental Setup

The experimental setup to evaluate the self-sensing ability of asphalt with embed carbon fibers, is also described in previously published works, aimed to develop a self-sensing carbon fiber composite (SSCFPC) sensor with the main objective of prototyping SSCFPC specimens and studying their R behavior when an external load is present. The carbon fibers utilized are characterized by unidirectional micro carbon fibers.

For measurements of on fabricated specimens, it was added a specially designed electrode at each measurement test point. Fabrication of the electrode’s needs to be made in a such way to enable a larger number of contact points available during operation, always maintaining electrode to composite conductivity, within mind everyday handling and usage as a sensor, for monitorization as part of a structural monitoring network system.

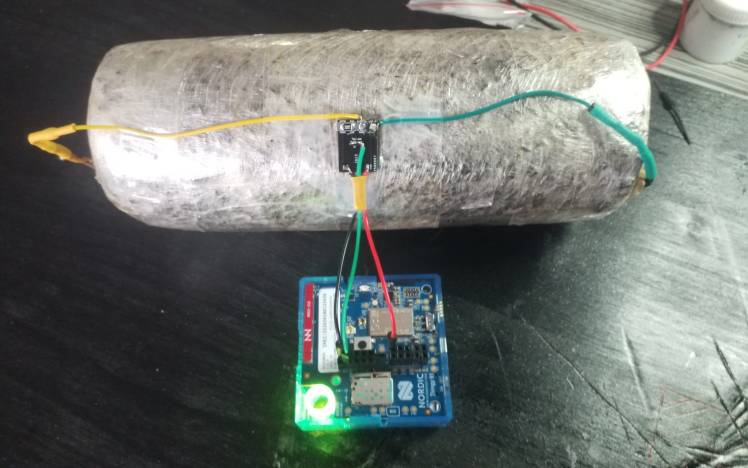

Measurements of R will be made using a two-probe technique, The selection of a two-probe electrode design was based on the simplicity of manufacture, as well as considerations in everyday use as a sensing unit when deployed for remote monitoring. Direct current (DC) was selected to analyze R measurements, using Nordic's Thingy 91 developer board.

Figure 8 – One Asphalt specimen wrapped in plastic film connected to the Nordic's Thingy91

Credits

Aeon

During my daily work activity I do Research , Prototype and Deployment of Smart AI enabled Technology Solutions. I also Advise and Mentor technology solutions to individuals and organizations (enterprises and institutions). I prototyped and about to publish the 3rd scientific paper on self sensing carbon fiber composite materials for active structural monitoring , and for the past 4 months now, I've been prototyping smart DAC devices to connect such materials to and edge server. The main objective, give life to a structure, by seamlessly integrating any structural element into a remote, live active (or passive) monitoring network with usage of artificial intelligence technologies all together

Leave your feedback...