Diy - Battery Powered Hot Styrofoam Cutter

About the project

I needed a hot wire cutter to slice up some Styrofoam for my BB8 project. I looked at buying one but they were not as cheap so I decided to make one of my own and I was so pleased with it I decided to share it with anyone else who wants to make one.

Project info

Difficulty: Easy

Estimated time: 1 hour

Items used in this project

Hardware components

Story

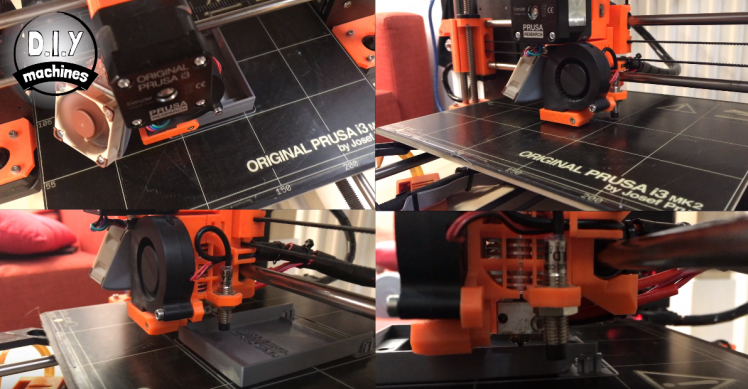

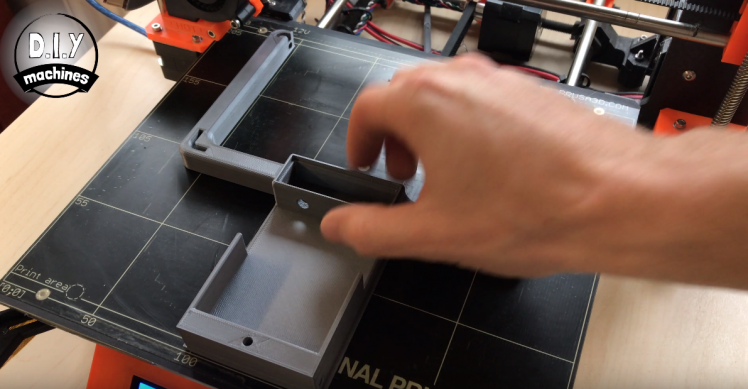

Step 1: Print the 3D Printable Parts

You'll need to be begin by printing the 3D printed components. You can find the files available to download here: https://www.thingiverse.com/thing:2718709

If you do not have a 3D printer, perhaps someone you know can print them for you or you could fashion a frame out of wood or some other material that you feel comfortable working with.

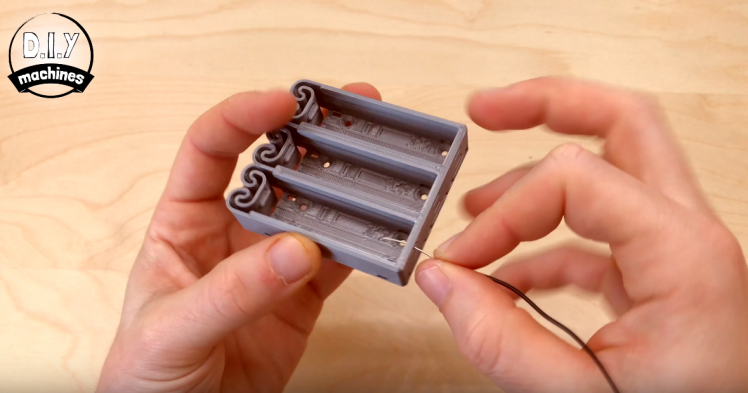

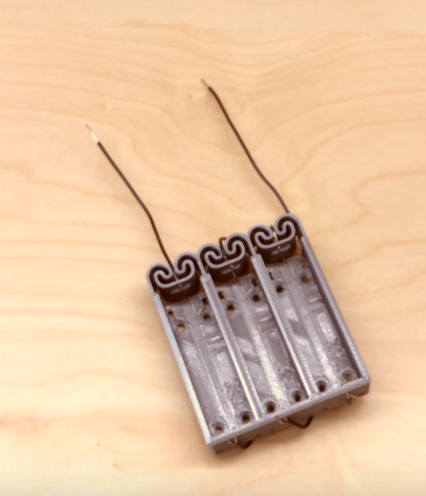

Step 2: Assemble the Battery Pack

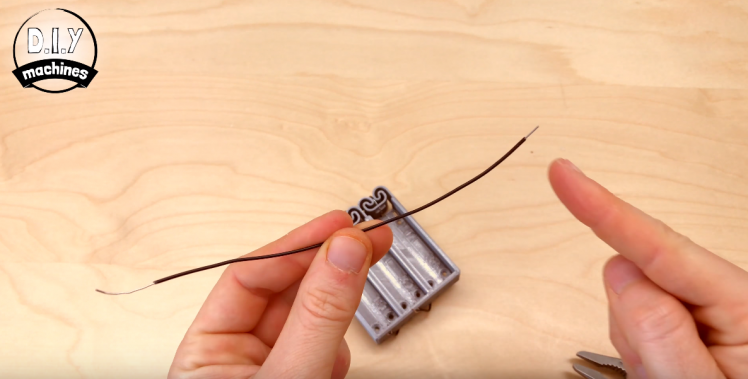

You'll need two 14cm wires to begin with, with a large amount of each wire striped back.

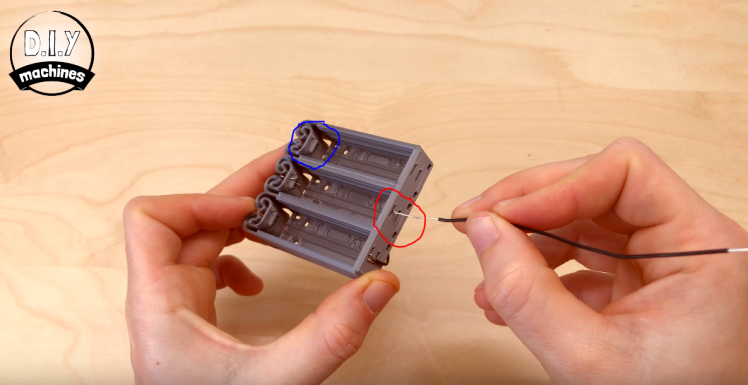

Follow the images carefully, the first wire needs threading through the hole in the bottom left of the battery holder (as shown) and then bending around and feeding back through the hole below it. This should leave a length of it exposed in the battery holder for the end of the battery in that compartment to press against and connect with.

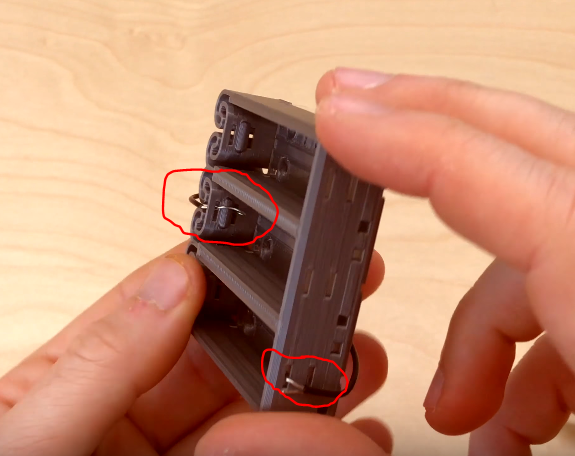

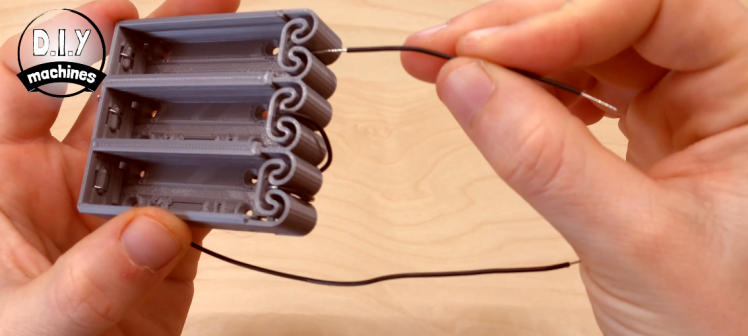

Then take the other end of this wire, fold it under the back of the battery pack and up towards the top of the centre battery holder. This time we'll insert it through the hole at the top of the central holder, and like before, fold the wire back through on the hole below it so it can connect with this battery. In effect we are wiring these in series. By the end of this step your assembly should look like the final image - look where I have circled in red, this how the wire should be folded.

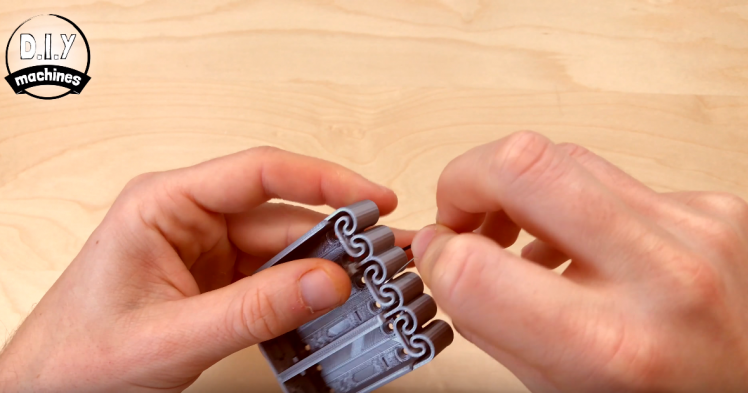

Step 3: Assemble Battery Pack - Part 2

Now we need to repeat what we did in the previous step, but this time from the connection circled in red, round underneath the battery pack and up to the connection circled in blue.

Step 4: Assembling Battery Pack - Part 3

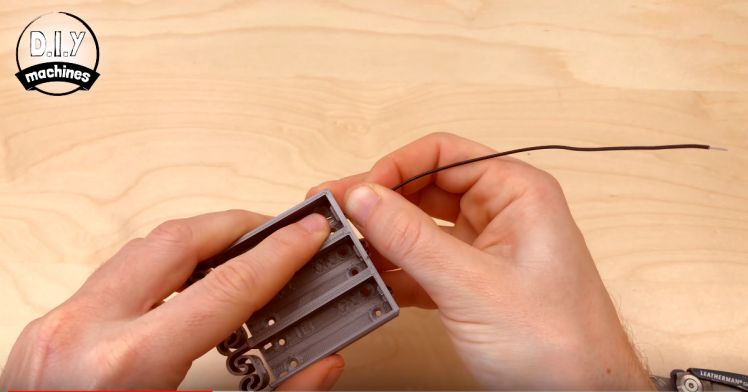

We need one more 14cm wire, but this time only one end needs a lot exposed, the other only requires enough to solder it in a short while. This needs threading through the bottom right battery connection and then folding under the battery pack so it's available at the top of the pack for soldering soon.

You'll also need a 4cm length of wire, again this time with only one end with a large amount exposed. This wants connecting to the top left of our battery pack (by threading it through and folding back round on itself as we have done with all the others so far) and the short exposed end should also be pointing up with the longer wire we fitted at the start of the step.

We will solder these to our other components at a later step.

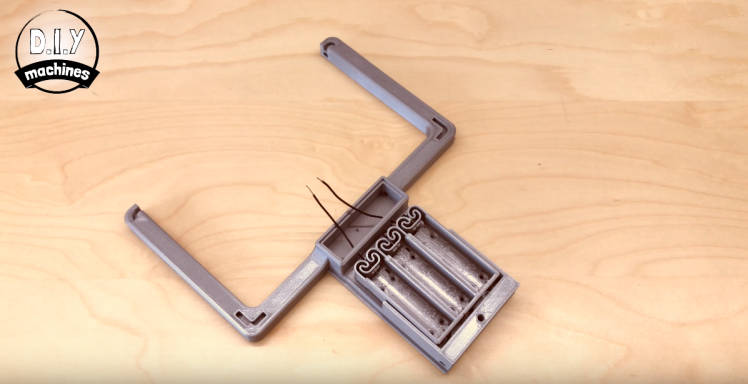

Step 5: Glue the Battery Pack in Place

Take the main printed assembly and thread the two wire from our battery pack through the two holes in at the top of the handle. Use some glue (I've opted for my favourite hot melt) to fix it into place.

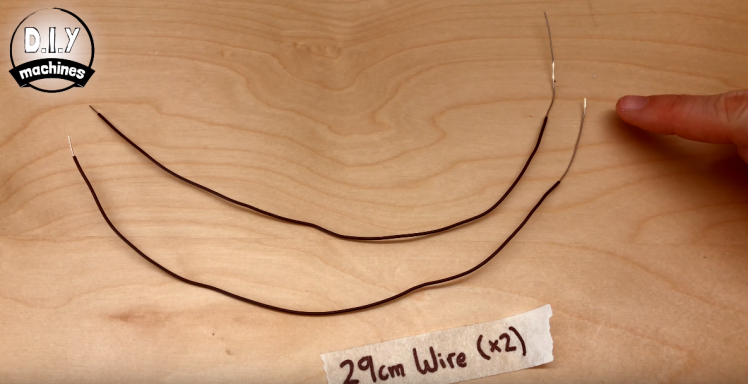

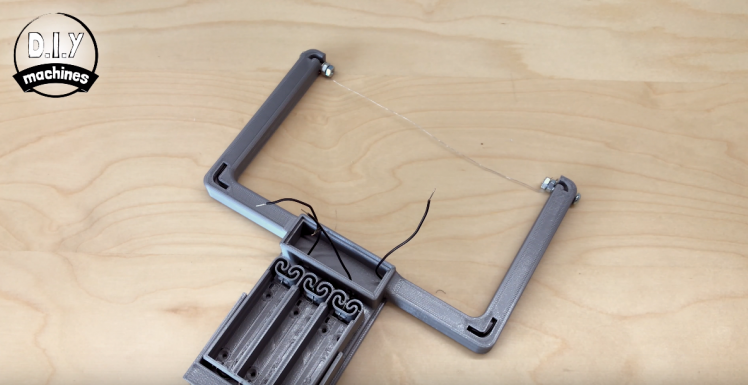

Step 6: Thread Through the Main Cables

The main cables that connect to the hot wire need to be about 29cm in length, and one end of them needs about 30mm of the wire exposed.

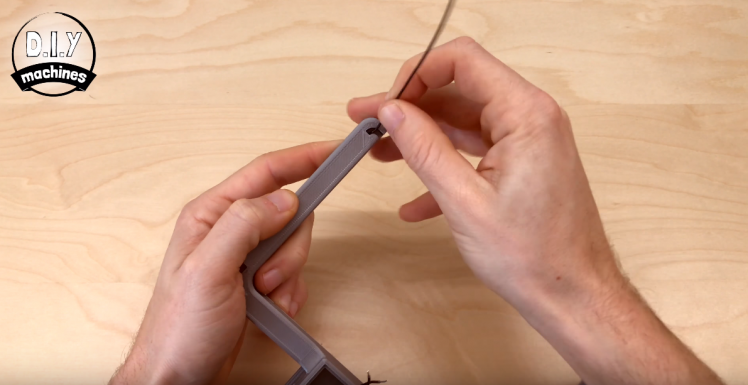

Each one need threading through the hollow tube inside the two side arms. It's best to start at the tip of one of the arms and thread the end with the small amount exposed in, at the corner you can fish it out with a small screwdriver, pull it though and then push it back down around the corner through the rest of the arm. Again when you see the end you can pull it through again.

Only pull the wires through enough so that the insulation at the other end stop at the opening.

Step 7: Add Some Nuts an Bolts...

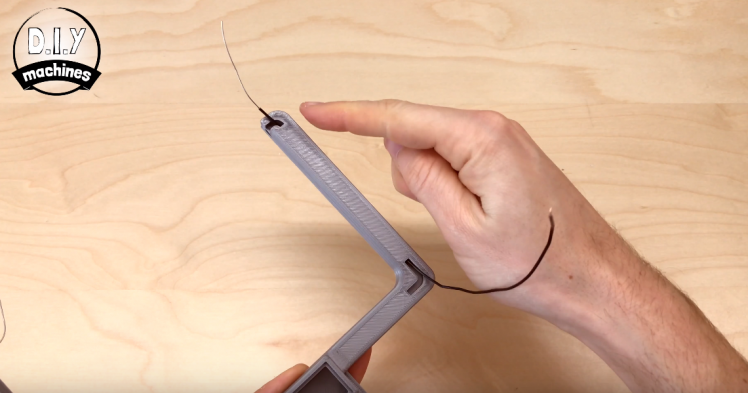

Grab four M4 nuts and four M4 20mm long bolts.

At the top of the arm, screw the bolt in from the outside so the thread shows on the inside of the arms. Now wrap the un-insulated wire tightly around it and then add a nut onto the bolt and tighten it so it's pressed up against the wire. This provides our connection to this wire.Add the second nut but leave this one untightened for time being.

Repeat these steps on the other arm.

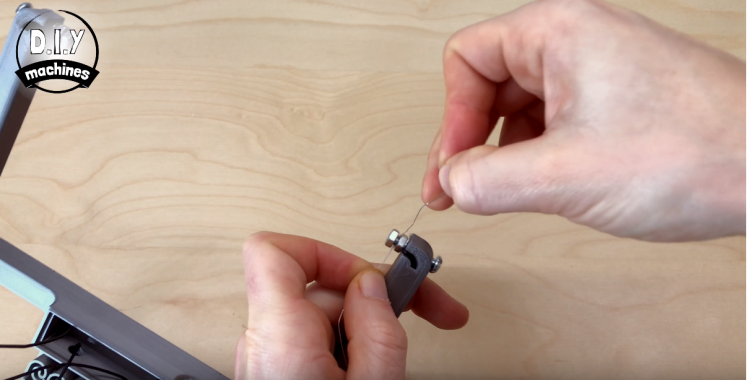

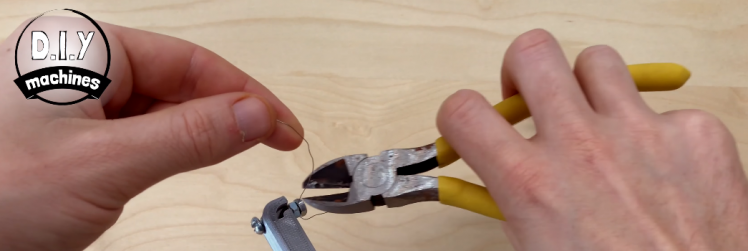

Step 8: Add Our Nichrome Wire

Wrap one end of a piece of 32 SWG Nichrome wire between the two nuts on one of the arms. Wrap it around a few times and then tighten the last nut we put on the bolts so as to clamp the Nichrome between the two nuts.

Repeat this on the other side but it is important to keep the stretch of wire between the two arms as taught as possible so as to improve it's ability to cut accurately.

Trim the ends of the Nichrome wire and tuck any remaining little bits around the nuts and bolts.

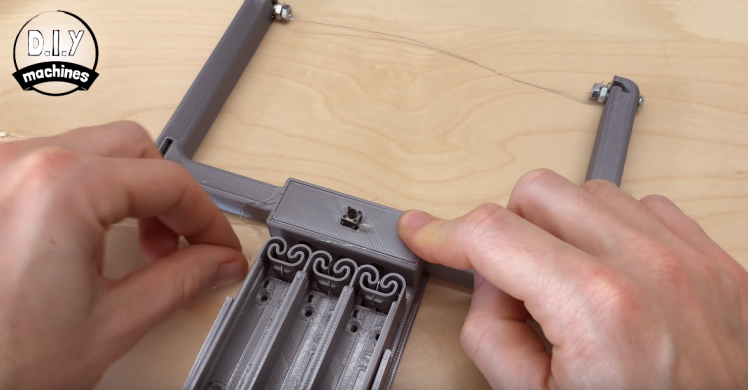

Step 9: Solder the Wires and Switch Together

First, solder the two right most wires together.

Now push the legs of a small momentary switch through the small cover piece (a 3D printed component) and solder this between the two left most wires.

Once this is done, fold the wires into the small compartment. (I used some hot melt glue to hold everything in place and to help prevent any short circuits). The lid itself with the switch can then be glued in place.

Step 10: Add Batteries and Go!

Add three AA batteries (ensure if they are re-chargeable that they are well charged). Then screw the cover in place with a 10mm M4 bolt and you're good to go.

Take note that normally batteries are inserted with the plus and minus ends alternating but in this design they all need to be the same way up.

Step 11: A Few Words of Caution...

This heats up very quickly and will hurt/burn/damage you or other items when it is powered on. Once turned off the wire can still remain hot for 30 seconds or longer so be careful with this and don't let children use it unsupervised.

I've used it to cut Styrofoam but you may find it's suitable for other materials as well (perhaps cheese?!). Let me know in the comments if you find it's good for anything else.

Also, if you like what I've created, please consider supporting me on Patreon: https://www.patreon.com/diymachines

Leave your feedback...