Diy Helping Hands Soldering Station

About the project

In this tutorial I am going to show how we can make a super flexible helping hands soldering station using basic materials which are low coast and can be found easily in nearby stores. This 4$ helping hands soldering station looks decent and can perform all the tasks that a commercial helping hands soldering station can do.

Story

Supplies:

- 10 Gauge plastic coated single string metal wire

- Block of wood (15x30 Cm)

- Alligator Pins

- Some different sizes of steel rods

- Solder Holder (Or) Thick metal wire

- Solder tip cleaner (Or) A small container with steel scrubber

- A (7X10m) metal sheet

- Wood Finish Oil

- 5V White LED Light

- Hand drill and other tools

Step 1: Making Flexible Arms:

- Take the hand drill with a long 5mm diameter rod.

- Mark a point on rod for length of the arm.

- Take the metal wire and roll on the rod to make the spring.

- Similarly make few more springs.

- Take the same metal wire and double it using drill.

- This double wire is going to act as core for helping hands.

Step 2: Drilling Holes on the Wood:

- Take the wooden block and mark the positions where you want to place your helping hands, solder holder, lead wire holder and solder tip cleaner.

- Drill the appropriate holes at the marks you made.

- For placing the helping hand drill a hole of spring diameter.

- Inside the same hole drill a hole of core diameter.

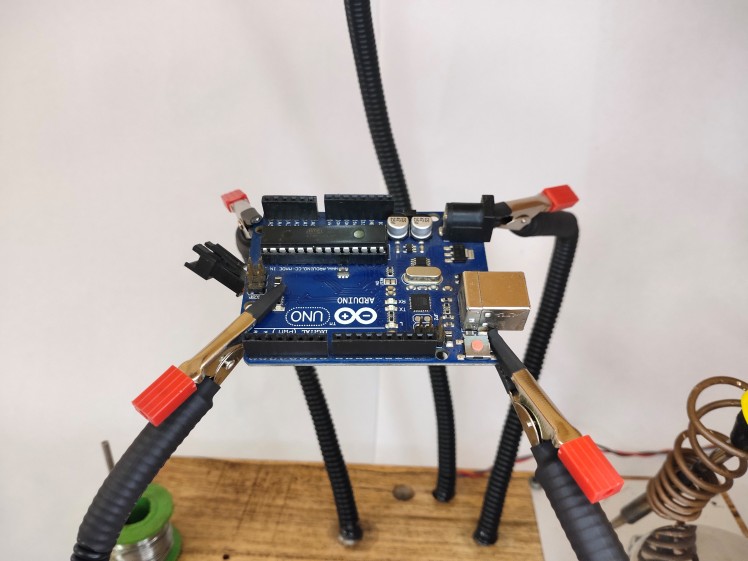

Step 3: Installing Helping Hands:

- Put the cores and springs in the respective holes using glue.

- Take the heat shrink tubes and the alligator pins.

- Fix the alligator pin using super glue.

- After the glue dries position the heat shrink tube and shrink it.

- Put the heat shrink tubes on the teeth's of the alligator pins.

- Glue a 5V LED light on a flexible hand.

Note: You can even put a magnifier and a small DC fan on the flexible hand.

Step 4: Final:

- Fix the container with screws on to the wood.

- Place the scrubber and put the lid.

- To this lid make a opening.

- Fix the solder iron holder and a small rod for lead wire holder.

- Apply the wood finishing oil.

You can use a commercial solder holder and commercial solder tip cleaner instead.

Credits

mukesh-sankhla

Tech Educator | Content Creator | Developer | Maker - Simplifying technology through hands-on learning. Creating high-quality tutorials, projects, and insights on electronics, IoT, robotics, CAD, 3D printing, and software development at Empowering students, professionals, and makers with practical, accessible, and inspiring content.

Leave your feedback...