3d Printed Car Part

About the project

This project describe how I avoided buying an expensive kit to replace a broken plastic part of my car.

Project info

Difficulty: Easy

Estimated time: 1 hour

License: GNU General Public License, version 3 or later (GPL3+)

Story

Details

Making mistakes ..

At the beginning I just wanted to remove my glove box in order to change a blown fuse, unfortunately I also broke a plastic hinge in the process.

The glove box area, the blue part is the replacement, the black one is the original.

I looked on ebay for a cheap replacement, nothing was available. One specialized website offerred a complete glove box replacement but it was really expensive. Crazy glue didn't work very well as the part must be a bit elastic when the glove box is inserted or removed.

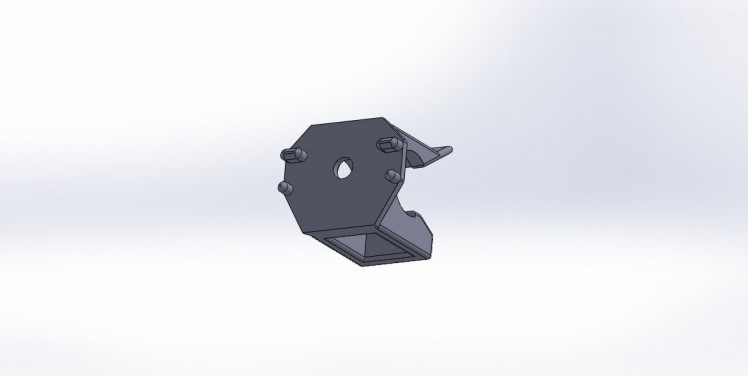

Thankfully, the right hinge survived, like an endangered species, I was able to clone it

Since I had almost unlimited access to Up Box 3D printers witch print fantastic ABS parts, I thought 3D printing could be my saviour.

The design

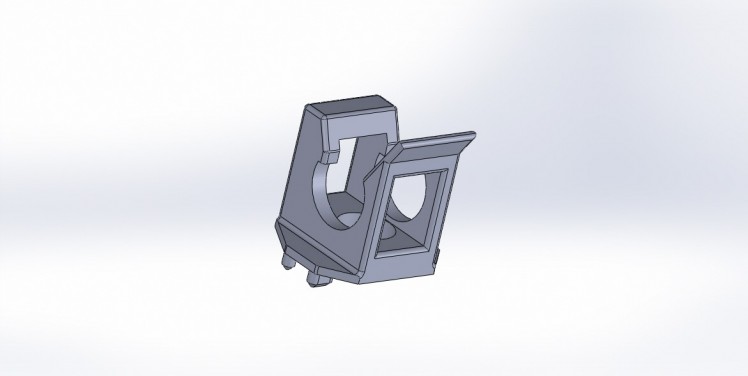

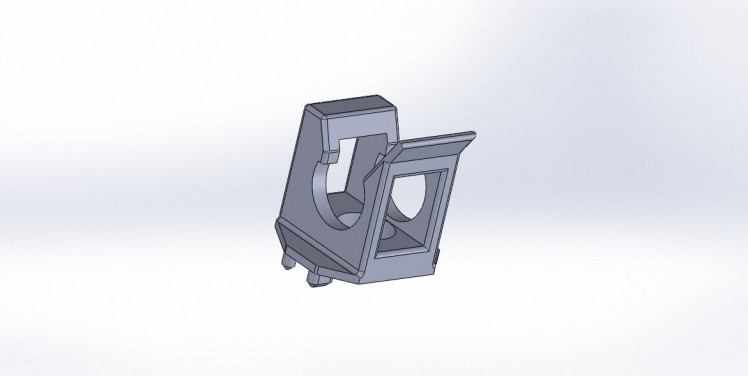

I decided to take measurements and recreate the part using 3D printing. Since the pastic i'll be using has different characteristics, I didn't do an exact copy. Also injected plastic parts are usually complex for various reasons including being moldable, reduce plastic volume etc ...

The 3D print

I printed two copies with various orientations, one broke right away as expected because the Z axis orientation made the legs very fragile. I installed the second one 3 years ago, it's still does its job perfectly as of today.

The 3D printed clone, who said clones were color accurate !?

Leave your feedback...